Geogrids

Solution Overview

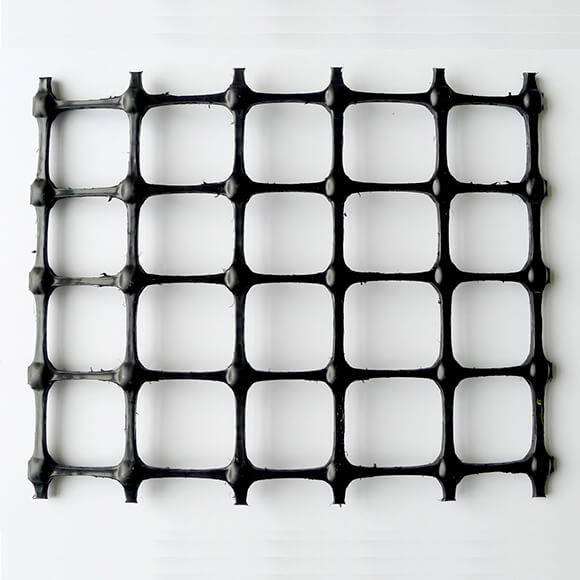

A geogrid consists of a 2-dimensional arrangement of integrally connected tensile elements or ribs that form a grid or net-like structure, usually supplied in roll form. Manufactured from polymers, geogrids are classed as geosynthetic products; this is a broad product classification that includes geotextiles and geomembranes alongside other minor categories.

Tensar geogrids are typically manufactured from oriented high-density polyethylene (HDPE) or polypropylene (PP) for durability, stiffness and strength. The junctions between ribs are integrally formed giving them high strength and structural stability. The design quality and effectiveness of Tensar geogrids has made them the go-to solution for local authorities in the UK and around the world.

Polymeric geogrids are used to solve civil and geotechnical engineering problems in or on the ground. They primarily provide soil stabilisation or reinforcement function, to add to or enhance the properties of soil or aggregate materials.

Geogrids were invented by our company founder, Dr Frank Brian Mercer, who patented his design in 1978. Since then, Tensar has been at the forefront of product innovation globally and manufactures the most advanced solution on the market – Tensar® InterAx®.

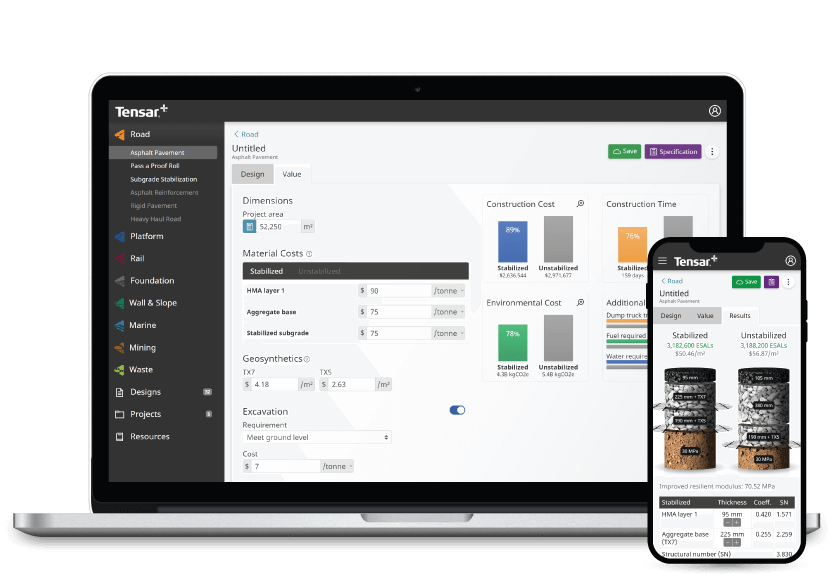

Need a Tensar design for your project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

What is geogrid?

Geogrid is a type of geosynthetic material that provides a stabilisation and reinforcement function to aggregates and soils. The design comprises a two-dimensional pattern of ribs to form a series of apertures or open spaces, which enables geogrid reinforcement to stabilise and reinforce earth materials. This geogrid mesh effectively interlocks with the surrounding materials, enhancing the overall performance.

What are geogrids used for?

Geogrids primarily provide a stabilisation or reinforcement function, to enhance the performance of soils. They also provide separation between soil and aggregate layers and are used widely in civil engineering applications.

Geogrids can be used for the following applications:

- Building stable working platforms over soft ground conditions

- Enhancing the service life of roads, pavements and trafficked areas

- Improving the long-term performance of paved and unpaved roadways by minimising aggregate movement

- Reinforcing soil retaining walls

- Foundation and embankment support

- Railway trackbed improvement

How does geogrid stabilisation work?

Geogrids work efficiently because the apertures between ribs allow the aggregate to strike through and interlock with the geogrid reinforcement. Provided the geogrid is stiff enough, the rib profile deep enough and the junctions strong enough, earth materials are confined within the apertures to prevent the movement of aggregate. This forms a new geogrid/aggregate composite material with improved strength and resistance to deformation.

Testing and experience have shown that Tensar geogrids support the function of separation when properly graded aggregate fill is used. Our geogrids maintain drainage and are not prone to “blinding out” or clogging which may occur with a geotextile used as a separation layer.

How do geogrid solutions reinforce soils?

For soil reinforcement geogrid applications, load must be transferred between the soil and the geogrid. The transverse ribs of uniaxial geogrids provide an efficient mechanism for load transfer by abutment rather than friction alone. The high tensile load in the geogrid is carried by the longitudinal ribs. They must be capable of sustaining such high loading for the full life of the structure (often up to 120 years), requiring durability and long term strength and stiffness.

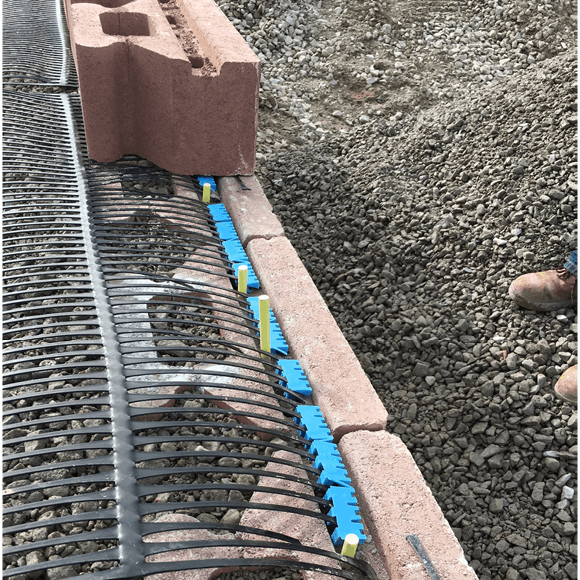

Tensar geogrids are routinely excavated through and punched through in order to place underground utilities. The innovative design of geogrids allows them to withstand the stresses associated with trenching and backfilling. This ensures soil reinforcement remains effective after installation.

What are the types of geogrids?

The main types of geogrids are the following: uniaxial geogirds, biaxial geogrids, triaxial geogrids (TriAx®), Tensar H Series (HX) geogrids and Tensar InterAx® geogrids.

Who invented geogrids?

Geogrids were invented by Dr Frank Brian Mercer and patented in 1978. Prior to its acquisition, Mercer founded the company Netlon which went on to become Tensar. Continuing the tradition of innovating geosynthetics, Tensar still stands today as the world leader in geogrids, investing in the research and development of new products such as Tensar® InterAx®.

To learn more, see our booklet on Dr Frank Brian Mercer and the invention of polymeric geogrids.

Comparing Tensar Geogrids with alternative soil reinforcement solutions

The efficiency of the interlock and confinement provided by a geogrid is dependent upon its physical characteristics (in-plane stiffness, junction efficiency, rib profile) and compatibility with the aggregate (particle size and type). Different geogrids with the same short term QC strength can have widely different characteristics dependent on the method of manufacture, the joint type, rib profile and polymer used.

For soil reinforcement applications, the geogrid mesh must have proven long-term strength and stiffness characteristics as well as high durability. Geogrids vary in their long-term characteristics, dependent upon the manufacturing methods and the polymer used. Tensar uniaxial geogrids are certified for 120-year design life in a wide range of soil pH and chemically aggressive environments.

See below how Tensar’s geogrid solutions directly compare to other geogrids and ground reinforcement products.

How are geogrids made?

Geogrids mesh products are typically made from polymer materials, including polyester, polypropylene, polyethylene, or polyvinyl alcohol. They can be woven or knitted from yarns; punched into a polymer sheet; extruded through rotating die heads to create a net structure or welded from strips of material.

Punched and drawn geogrids

Molten polymer is extruded into a sheet of defined thickness and a pattern of holes is punched into the sheet. The punched sheet is then stretched in either a single direction to form a uniaxial geogrid or in two directions to form either biaxial or multi-axial geogrids.

Extruded geogrids

Molten polymer is extruded through rotating “die heads” each with a series of “holes” which allow the creation of a “net” type structure. The geometry of the resulting net or geogrid is dependent on the die/extrusion configuration with both uniaxial and biaxial products available.

Welded geogrids

Polymer strips are manufactured and are then bonded together to form a square or rectangular grid shape. The bonding would typically be carried out using heat.

Woven geogrids

Woven geogrids are fabricated by weaving polymer yarns together, or sometimes knitting polymer yarns together to form a net/grid-like structure. These woven products are often then coated with other polymer materials such as polyvinyl alcohol (PVC) to form the final woven geogrid.

Geogrid/geotextile composites geogrids

Can be formed by bonding a geotextile separator fabric to the completed geogrid manufactured by the methods above.

It is important to note that whilst the inclusion of a geogrid in a roadway or platform would be expected to have a beneficial effect, these benefits will not be the same for each grade of geogrid product. In fact, research has shown that the manufacturing method can have an influence on the expected performance of the resulting road or platform.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)