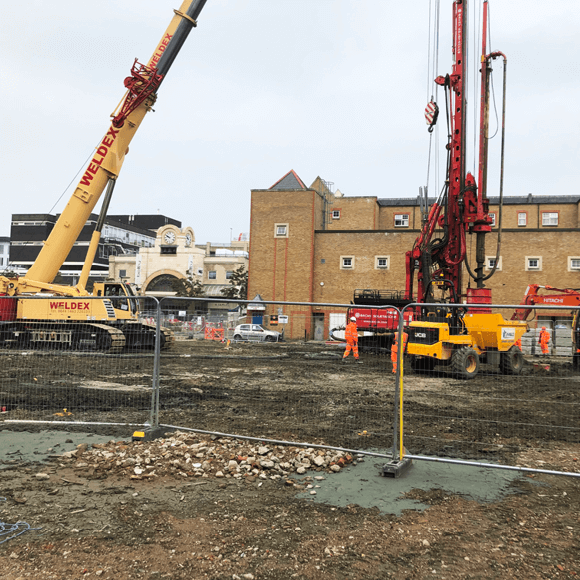

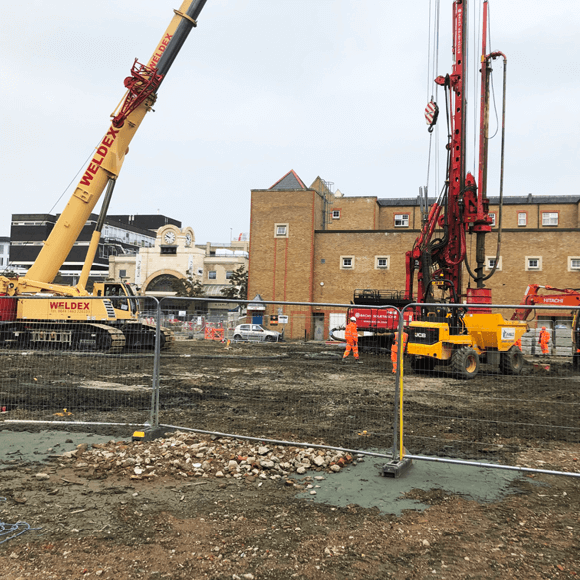

Marketfield Way

Tensar’s T-Value design method delivered a piling mat that was 33% thinner than the original design, cutting construction time and costs, with less environmental impact.

Benefits

- 33% thinner piling mat

- 20% savings in construction cost time savings

- 18% reduction in construction programme

- Reduced carbon emission by around 240t CO2e

Vinci Construction UK needed to install a 5,000m2 piling mat for a development in Redhill town centre. The original design required excavating the underlying peat and weak clays to 1.2m and replacing them with recycled engineering fill, to create a safe working area at ground level. However, after attending a T-Value design method workshop, Vinci asked Tensar to see if savings could be made.

The T-Value design method analysed the full benefits of a Tensar mechanically stabilised layer using locally available demolition granular material designed to take project specific ground conditions and loading into account to provide a safe working platform for site operations. Tensar’s proposal reduced fill volumes and excavation quantities, cutting installation costs by around 20%, the construction programme by approximately 18%. It also minimised the environmental impact by reducing embodied carbon by around 240t CO2.