Roads, Pavements & Trafficked Areas

Speed up construction and reduce costs with geogrids

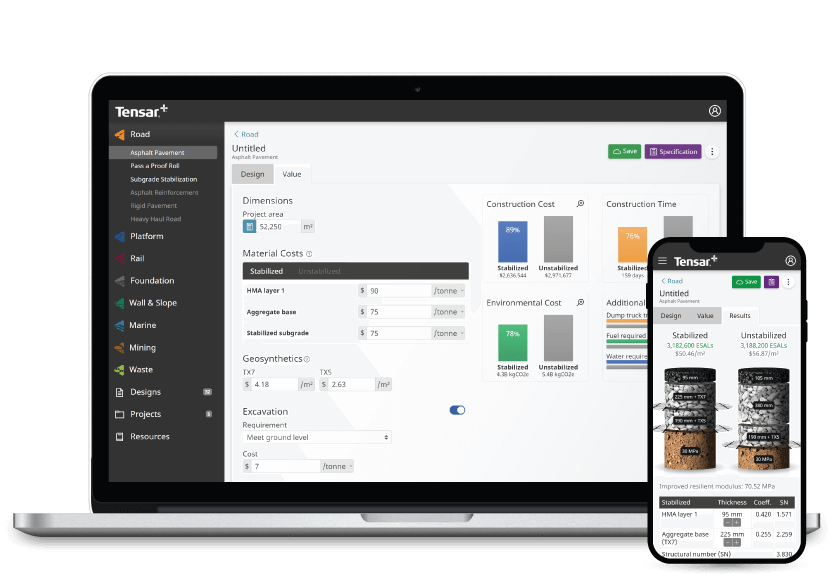

Geogrids for roads strengthen the unbound layers enabling a reduction in layer thickness by reducing the volume of non-renewable aggregates and other pavement materials. Utilising Tensar geogrids in road construction will reduce costs, time spent on projects and embodied carbon contributing to sustainability practices in construction.

Tensar’s geogrid technology is primarily used in road construction, however can also be utilised for:

- Ground and soil stabilisation

- Capping layer and subbase reduction

- Improving the performance of paved and unpaved roads

- Increasing bearing capacity of heavy-duty pavements

- Tensar’s asphalt interlayer products mitigate cracking and improve fatigue life of asphalt surfacing

Request a free design assessment to discover how our geogrid solutions can enhance the longevity and increase the value of your unpaved roads, pavements and trafficked areas project.

Paved Roads

Paved roads and trafficked areas can include either flexible or rigid pavement construction. Flexible pavements are typically surfaced with bituminous bound materials, while rigid pavements incorporate a concrete surfacing.

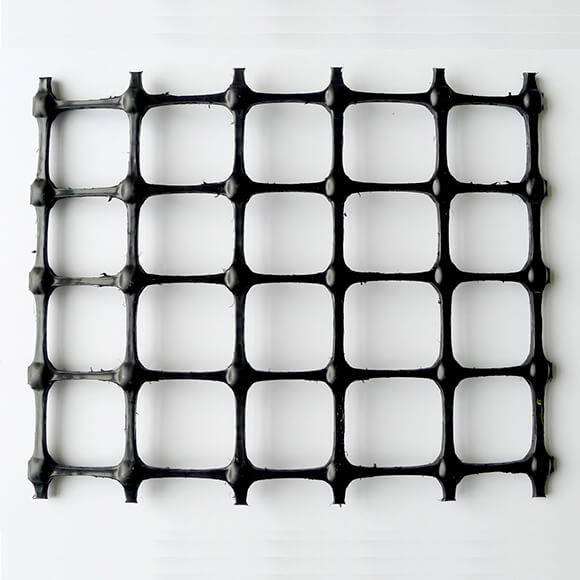

Both types of pavements require a strong stable foundation, typically one or more layers of unbound aggregate. The strength and stiffness of an unbound layer can be enhanced by incorporating a suitable stabilisation geogrid, leading to an increase in trafficking performance and pavement life.

Over very weak soils a geogrid stabilised layer can be used as an alternative to excavation and replacement, chemical stabilisation, or thick capping layers.

Read More

Flexible Pavements

Flexible pavement structures often fail prematurely because of progressive lateral and vertical displacement, and a weakening of the subgrade and unbound aggregate layers. Tensar geogrids in pavement construction improve the overall stiffness of paved structures that support traffic. This is achieved by interlocking with aggregate and confining particle movement to create a mechanical stabilised layer (MSL). Utilising geogrids in road construction leads to enhanced trafficking performance, minimising maintenance and rehabilitation common to flexible pavements.

Surface cracking contributes to flexible pavement deterioration, but using Tensar asphalt interlayer products installed below the surfacing layer becomes the hidden strength in the road. Crack propagation is inhibited, and fatigue performance enhanced. Pavement performance is improved, and ultimately maintenance and life cycle costs are reduced.

Read More

Rigid Pavements

Tensar geogrids in pavement construction can help you build stronger, longer-lasting rigid pavements. Building a rigid pavement over a mechanically stabilised layer (MSL) and incorporating Tensar geogrids provides greater support than a thicker, aggregate base layer. This results in a more resilient pavement foundation that will not lose strength over time.

The geogrid interlocks and confines the aggregate base, resulting in less deformation during the pavement’s life. The confinement reduces the potential for particle movement, limiting foundation deformation and contamination of the aggregate base with the subgrade soil.

Most concrete pavement problems stem from poorly performing joints. Poor load transfer creates high slab stresses, contributing to faulting, pumping and corner breaks. The Tensar geogrid MSL provides a stiff resilient layer, which minimises the potential for differential movements of the concrete surface that initiate faulting and corner breaks.

Heavy Duty Pavements

Structural design and construction is essential for heavy-duty pavements. Many serve high-stress applications including intermodal, port and loading facilities, airport runways, warehouse/distribution centres, and heavy truck corridors. Heavy duty pavements frequently deal with slow moving and static traffic load with ultra-high load magnitude. They feature a range of surfacing, but most often it will be asphalt, concrete or block paving.

By integrating Tensar geogrids into heavy-duty pavement designs, it is possible to extend the design life of heavy-duty pavements by a factor of three to six times, leading to significant life cycle cost savings.

Unsurfaced Roads

Most connecting roads, farm to market roads, haul roads, access roads and temporary roads have no paved surface. Or they’ll have a thin, non-structural spray and chip surface for waterproofing and dust control. Unsurfaced roads depend on unbound layers to protect the subgrade and maintain a smooth road surface.

As part of enabling works, weak or variable subgrade soils need protection from further deformation. Post construction, the subgrade must be protected from traffic loading that can lead to deformation of the subgrade and failure of the road.

Tensar geogrids in road construction are designed to interlock with and confine the aggregate, creating a mechanically stabilised layer (MSL) that evenly distributes the load. Geogrid reinforcement for roads, increases bearing capacity, ensures longer-term stability and performance. Strengthening the aggregate layer with road geogrids enables layer thickness to be reduced. By reducing the volume of non-renewable aggregates, project costs, time and emissions are reduced, contributing to sustainability objectives.

Read More

Asphalt Reinforcement

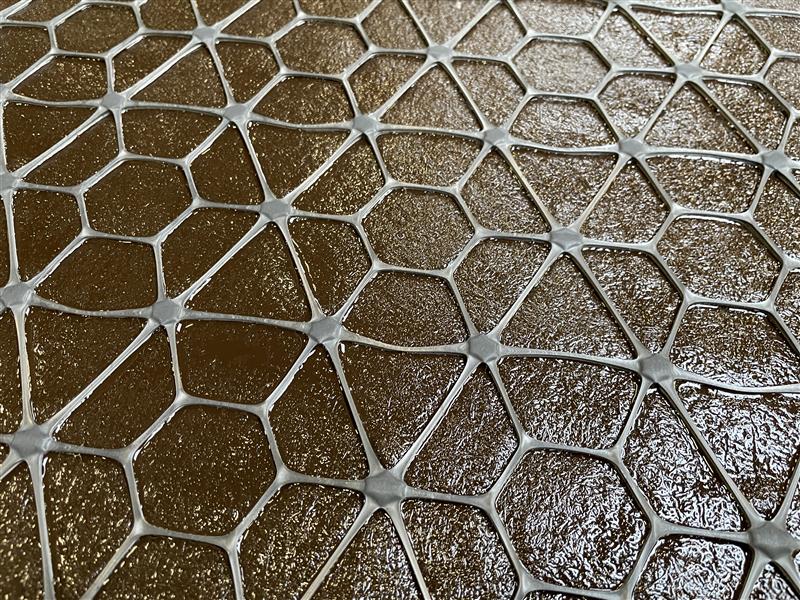

Surface cracks in the asphalt propagate allows water to ingress, weakening the foundation layer and subgrade, and leading to further deterioration and permanent loss of strength. Asphalt reinforcement reduces reflective cracking in asphalt surfacing and reflective cracking induced by thermal movement of substrates or shrinkage of subsoils. Reinforcement of an asphalt layer can also improve its life by delaying the onset of fatigue cracking.

Tensar has a range of asphalt interlayer composites and geogrids for roads designed to interact with the bitumen bound layer: to adding tensile stiffness, limiting strains and reducing crack development and size. Composite interlayers comprise a geogrid bonded to a fabric that together provide reinforcement and act as a Stress Absorbing Membrane Interlayer (SAMI) and a moisture barrier.

Need a asphalt design for your roads project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Request Design Assessment