Cut & Fill Excavation Method: Meaning & Calculations

Date: October 21, 2025

Cut and fill is an earth-moving technique used to create level surfaces by removing soil from high points (cut) and redistributing it in low areas (fill). The volumes of cut and fill are influenced by the initial topography and the desired finished levels across the site. By adjusting the alignment and finished level, it may be possible to achieve a balance between cut and fill volumes for the project, reducing the need to import or export soil and minimising transportation and material costs.

From roads and railways to embankments, whatever project you’re working on, understanding the cut and fill process and knowing how to achieve balanced earthworks is essential for an economic design. Accurate calculations of cut and fill volumes are an essential part of the process, as is a thorough understanding of the site geology and topography.

Excavation volumes can be greatly influenced by the presence of weak soils. These will often need to be removed or treated before construction commences. As an alternative, if there are weak or variable ground conditions, geogrids may be used to stabilise the subgrade, thereby reducing cut volumes by avoiding the need to excavate and remove weak soil. In a similar way, embankment foundation systems may be used to avoid the need to excavate and remove weak soils before embankment construction. Fill volumes can also be reduced by the use of reinforced soil techniques to steepen embankment side slopes.

Read on to discover more about what the cut and fill excavation technique is, where it fits into the construction process, how to calculate cut and fill volumes and key advantages. Along the way, we’ll also explore the issues you may encounter with cut and fill methods and how to overcome them.

Looking for something in particular? Use the links below to navigate straight to it:

- What is the cut and fill excavation method?

- Selecting soils in cut and fill construction

- The cut and fill process

- Advantages of the cut and fill method

- Calculating the cut and fill method

- Issues you may encounter with cut and fill

- How can we reduce earthworks volumes in cut and fill operations?

- Cut and fill case study: Robroyston Link Road

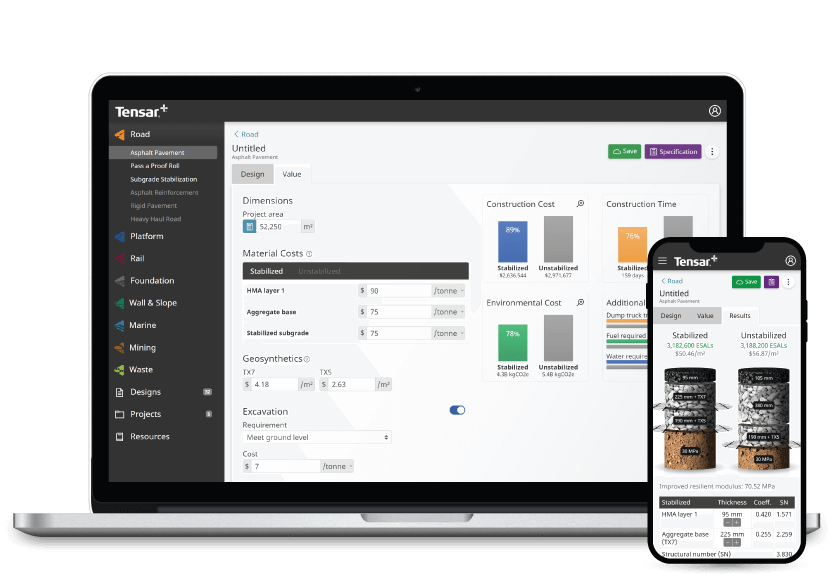

Start designing more efficient cut and fill excavations with our free geotechnical design software, Tensar+, or get in touch to find out how we can support your next project.

What is the cut and fill excavation method?

Cut and fill is a construction method where soil from higher ground is removed and reused to fill lower areas, creating a level or appropriately sloping surface suitable for the site’s intended purpose. It reduces the need for imported or exported materials, cutting costs and material transportation.

When the volumes of cut and fill are carefully planned to balance one another, a process referred to as balanced earthworks, soil can be redistributed on site without the need for imported fill or the removal of spoil. By utilising material resources available on site, not only is waste reduced, but environmental disturbance is minimised.

Used across a range of construction projects, cut and fill excavation method can play a key role in road construction, foundations and embankments, railways, working platforms, retaining walls, slope stabilisation and bridge abutments. Understanding your site's ground conditions is essential for accurate calculations of cut and fill volumes. Some excavated material may be unsuitable for reuse. Without adequate site investigation, you risk having an excess or a shortage of materials, which could be costly and affect project schedules.

Cut and fill vs other excavation types

With various excavation types used in construction, the cut and fill method is specific to site preparation.

While cut and fill is used for levelling areas of uneven ground, other excavation activities (ranging from narrow trenches to large scale basements) can be carried out for specific purposes. Trenching involves digging narrow excavations and replacing soil to install utilities like water pipes and electrical cables – focusing on creating a path for infrastructure rather than reshaping the ground.

On the other hand, large scale excavations (as for basements) are used for deeper substructures.

Selecting soils in cut and fill construction

When levelling a site, a variety of soil types arise from the cut areas that can be used for fill on the project. However, not all soils are suitable for all fill locations. The type of soil that can be used and at what level will depend on the ground conditions and the structural requirements of the finished ground at that location. Some examples of soil material types and their potential for re-use are listed as follows:

Topsoil

Topsoil is the uppermost layer of soil and is usually removed and set aside before construction. It is a valuable commodity that is either reused on site or transported off site for use elsewhere. This material is usually unsuitable for structural fill and is typically reused for landscaping or restoration of the site’s natural vegetation.

Coarse-grained soils

Coarse-grained soils include a mixture of sand or gravel-like soils that compact well into the fill areas with adequate strength to support heavier loads. These soils will have a high permeability and will allow drainage. When well compacted, these soils can provide a stable foundation with minimal settlement issues.

Fine-grained soils (Silt)

Fine-grained soils consist of silts clays. Both materials have lower permeability than coarse grained soils and will undergo consolidation settlement over time under loadings. Due to these properties, these types of material are less suitable for use as structural fill unless treated or compacted carefully. Testing and soil modification for this material type are required before use. Without suitable drainage measures, the saturation of fine-grained soils can pose the risk of volume changes in the soil causing instability in the foundation.

Fine-grained soils (Clay)

Clay soil consists of finer particles than silt, which can hold moisture, expanding or shrinking with changes in water content. Due to this behaviour, it can be a more difficult material to use for structural fill as it is much more prone to volume changes over time, that can cause movement or instability of foundations. If clay is to be used, it may require special treatment, such as moisture conditioning or treatment with lime or cement for stabilisation.

The cut and fill process

The cut and fill process is essential for earthworks, levelling uneven ground, removing material from higher levels (cut) and redistributing it to lower areas (fill). Below, we will explore the key stages of the cut and fill process to understand how this technique is carried out.

Site survey

The process begins with site surveys. Topographical surveys map the ground, identifying high and low points that need to be levelled. A geotechnical survey will determine underlying soil conditions and identify any potential hazards to inform detailed planning. At this stage, advanced geotechnical investigations can be used to assess the classification, strength and stiffness properties of soils.

Our geotechnical design software, Tensar+, can help optimise the cut and fill volumes in balanced earthworks planning, while addressing weak ground issues and minimising land-take. Contact us to learn more about how we can support your next project.

Our geotechnical design software Tensar+, can help plan and optimise enabling works while helping you to create a smooth and durable surface for construction. Contact us to learn more about how we can support your next project.

Get in touch for a free consultation

Earthworks planning

The earthworks planning process directly influences project cost, timelines, and long-term project performance. Modern technologies have transformed earthworks planning operations. Rather than traditional ‘hand calculation’ methods, data is used to create digital terrain models (DTM’s) in proprietary software tools. These models allow engineers to overlay proposed site levels onto existing levels and calculate the required earthworks volumes. Proposed levels may then be adjusted, varying cut & fill volumes taking account of the suitability of various cut materials for different fill locations, to achieve a balanced earthworks design. These tools will optimise material distribution and flow on site, to minimise transportation costs and time, taking account of the likely available earthmoving and compaction equipment types and costs. The earthworks planning must also take account of topsoil removal and reuse, and the excavation and disposal of unsuitable soils.

Excavation (cutting)

Now that the earthworks planning is complete, the next stage is to commence excavation. Heavy equipment, such as bulldozers and excavators, will excavate the higher ground at the site. The different soil types will be identified and separated during this process. Large dump trucks or bottom-opening scrapers are used for material transportation.

Redistribution (filling)

The selected excavated material to be reused on site will be transported to the appropriate fill zones. Specific cut materials may be allocated for use at different horizons within a fill location. Bulldozers may be used to move material around a small area, while scrapers may be used to transport over short distances on relatively smooth terrain. For longer haul distances and over rougher terrain, large dump trucks will be used. Dust control measures may be needed along the haul road and wheel washing is required where dump trucks cross or utilise public roads. Water trucks with spray attachments are used for dust control and for moisture conditioning the soil prior to compaction. Where haul routes cross sections of weak soil, it may be necessary to construct temporary haul roads. The cost of these haul roads can be reduced by designing with Tensar+ software – helping to optimise materials and design efficiency.

Compaction and stabilisation

After redistribution to fill areas, the fill material will need to be compacted in layers to achieve the required density and strength. Traxcavators or motor graders are used to spread and level the material before heavy rollers are used for the compaction process. If areas of soft soil or weak subgrade are discovered before or during the process, these will need to be addressed. Without treating these areas, there is the potential risk of uneven settlement and stability issues.

In order to improve the weak and variable ground conditions, subgrade stabilisation techniques may be used to improve load bearing capacity. To create a stabilised layer, Tensar InterAx geogrids and granular fill (site won or imported) can be incorporated to improve stability and reduce the potential for deformation over time.

Advantages of the cut and fill method

The cut and fill method can help to improve project efficiency, costs and environmental sustainability. In this section, we’ll discuss how these benefits can improve construction planning.

Cost-effective

One of the key benefits of cut and fill excavation is that it can reduce the amount of imported material needed on a construction site. By using excavated material from the ‘cut’ areas to fill the lower areas on the site, costs are reduced as there are less requirements for imported fill. By utilising suitable cut materials on site, the cost of transporting and disposal of spoil is also reduced.

An example of the efficient use of site-won fill material is provided by the Costco Distribution Centre project in Northamptonshire. This involved building a 258m long and 15.5m high earth bund to minimise the new building’s impact on the surrounding landscape. The client also wanted to minimise costs by reusing all site-won materials using a cut and fill process. Tensar’s reinforced soil slope system was used to enable poor quality site-won clay soil excavated during the cut process as fill for the construction of the bund. The TensarTech GreenSlope System was utilised to form a 70° slope face to the bund – reducing the required embankment fill volume and maximising development space while providing a natural vegetated finish. Material costs were minimised by utilising the site-won material, with only a small amount of imported fill required, saving time as well as money.

The environmental protection barrier used site-won fill material, cutting waste and saving thousands in haulage and import costs.

The environmental protection barrier used site-won fill material, cutting waste and saving thousands in haulage and import costs.

Faster construction

Reusing excavated soil from the cut areas in the fill zones reduces the need for transporting additional fill material. Keeping material movement within a site can cut project times significantly, cutting down the time spent on handling and disposing of materials. Reusing materials on site not only increases productivity by utilising what’s already available, but it can also streamline operations.

Environmental impact

Minimising environmental impact is a growing priority in construction. Cut and fill supports sustainable construction practices by re-using the available resources on site, rather than sourcing additional non-renewable materials. Reusing excavated material reduces the need for importing materials or exporting a surplus – cutting costs and project timelines. This reduces embodied carbon emissions and local air pollution from transportation. It also reduces the noise and disruption to stakeholders local to the site by limiting the number of vehicle movements.

Calculating cut and fill volumes

Calculating the volumes of material to be excavated, transported, placed, and compacted is fundamental and critical for any civil engineering or development project. In the balanced earthworks approach, the objective is to achieve the required final surface profile with a balance between cut and fill volumes. Various methods are used to calculate these volumes, ranging from traditional manual approaches to sophisticated software tools.

Manual methods rely on basic geometry and mathematical calculations. Assumptions and simplifications are made to approximate volumes. Today, engineers are most likely to be using digitised terrain mapping and software tools to calculate earthworks volumes and material flow on a project.

Cross-section manual method

The cross-section manual method has traditionally been used for calculating cut and fill volumes for linear projects such as roads and railways. This method involves plotting parallel cross sections of both the existing and proposed ground levels at regular intervals along the project site. For each cross section, the cut and fill areas are determined by comparing the elevations of the existing ground and the proposed design at that specific location.

To calculate the volumes, the average cut or fill area of each pair of cross-sections is multiplied by the distance between them. However, the accuracy of the cross-method section depends on the interval distance chosen. Close intervals can improve the accuracy of the estimate, but require more time and effort to measure and calculate. Wider intervals are quicker but may reduce the accuracy of the results.

Grid manual method

Typically used on large, open sites, the grid method involves overlaying a uniform grid onto the plan of the earthworks area and manually recording the existing and proposed ground levels at each node of the grid. Calculating the cut or fill depth is determined by subtracting the average existing level from the proposed level at each grid cell. If the result is positive, the area requires fill. If the result is negative, it’s a cut area. Once this has been determined, you can then calculate the volume.

The volume for each grid cell is calculated by multiplying the cut or fill depth by the area of the grid cell. Total cut and fill volumes are found by summing all the individual cell volumes. The accuracy of the grid method depends on the size of the grid cells. Smaller grid sizes show more accurate results, but take more time, with more data needing to be collected. On the other hand, larger grids are quicker to calculate but can miss important variations in the ground surface – which can be essential for an effective design.

Mass haul diagrams (MHD)

For linear projects such as roads, railways and canals, it may be beneficial to develop a mass haul diagram to illustrate the volume of cut and fill material moved along the linear profile. It plots on the y-axis the net cut and fill volumes (cumulative material volume) along the linear profile x-axis. The mass haul diagram is used to compare the economics of different cut and fill regimes and varying finished surface profiles. Raising or lowering a road alignment on any section will immediately impact the earthworks economics and this may be seen on the mass haul diagram.

Automated methods

Today, most earthwork analysis is performed using software programs due to their accuracy and efficiency. Automated cut and fill calculations involve using 3D modelling software to analyse terrain data and determine how much material needs to be excavated or filled. This process begins by creating digital terrain models of both the existing and the proposed design, then calculating the volume differences between them. Graphical output from the software can highlight cut and fill areas with different colours based on elevation ranges.

These automated methods can help optimise the entire earth moving process, including equipment type and quantity, operating costs and scheduling to arrive at the most cost-effective approach. Shrinkage and swell effects (see below) can be accommodated in the analysis.

Swell effect

When soil is excavated, it loosens, reduces its bulk density and takes up a greater volume than the original in-place material. A ‘swell factor’ of up to 25% increase in volume may apply.

Shrinkage effect

When soil is placed and then compacted, its bulk density is increased and the volume reduced compared to the loose condition in transport. Typically, a shrinkage factor of 10-12% may apply to the soil.

Issues you may encounter with cut and fill

While cut and fill excavation is essential for various projects, it can still come with its own set of challenges. Read on to explore these issues you may encounter – and what you can consider doing to overcome them.

Unbalanced cut and fill volumes

If assumptions made for cut and fill calculations aren’t accurate, the site can end up with either a shortage or surplus of materials. Not only can this cause project delays, but it can also create additional costs. Overestimating fill volumes can lead to the need to export and dispose of excess materials, which can add further costs and logistics. On the other hand, if you underestimate the cut volumes, it could result in a shortage, requiring the need for additional materials to be imported to the site.

Having too much or too little material can significantly slow down the project's progress. Waiting for imported materials to arrive or the process of removing the excess can interrupt timeliness and impact productivity.

Unexpected ground conditions

Ground conditions can be highly variable and weather dependent, so when the excavation takes place, unexpected soil types, high moisture levels, and buried debris may be found. This can slow down excavation and movement of materials, affecting a project’s timeline, increasing costs and even requiring design changes. Geotechnical surveys during the planning stage are crucial, providing vital information to help teams understand the ground conditions better before excavation begins.

For any with weak and variable soil conditions, soil stabilisation techniques, such as installing a mechanically stabilised layer (MSL) using Tensar geogrids, can be used. While unexpected ground conditions often only become apparent during excavation, utilising geogrids in your design can help ensure construction goes ahead according to plan.

Drainage issues

In cut and fill operations, inadequate drainage planning can create serious issues – both during and after project completion. Water accumulation in low-lying fill areas and deep cut sections can result in project delays, soil erosion, and even bearing failure of the saturated layers. Excessive moisture can not only reduce soil strength, but it can also increase settlement risk and make compaction more difficult. This is why it’s important to integrate drainage design early on in the design process.

Ground consolidation

Where the existing ground includes layers of organic material or compressible soils, consolidation will occur under the weight of embankment construction. This may affect the final earthwork volumes. In some cases, embankment surcharge will be used to accelerate consolidation and minimise post-construction settlement. This will influence the cut and fill earthworks scheduling and final earthworks balance.

Safety

One of the key issues to consider when it comes to cut and fill operations is safety. The operation of large excavators, graders, and rollers, often working concurrently and in restricted space, requires careful planning to avoid incidents. The haulage of large volumes of material along a site as part of a cut and fill operation carries increased risk for site workers unless route segregation is employed and enforced. This may involve traffic control measures at pinch points or locating haul routes offline, reducing haulage efficiency.

As part of the Peels Pit Haul Road project for the Transpennine Route Upgrade, a haul road was required for the movement of materials along the length of the track works. Contractor BAM achieved a 46% reduction in the volume of imported fill by incorporating Tensar InterAx geogrid to stabilise the construction platform. This not only delivered significant cost and material savings, but also reduced the number of haulage movements on site. This improved the overall safety on the site by lowering the risk of vehicle interactions in areas where multiple machines operate nearby.

Using Tensar InterAx geogrid reduced fill volume by 46%, cutting haulage movements and improving site safety.

Using Tensar InterAx geogrid reduced fill volume by 46%, cutting haulage movements and improving site safety.

Shrinkage and swelling

This has already been mentioned in the previous section. Estimates must be made during the cut and fill planning stage for the expected shrinkage and swell of soil during different phases of the cut and fill operation. These assumptions will need to be checked when the earthworks operation is underway. If assumptions are incorrect, the volume calculations could be off by 5-10%. This may impact the cut and fill balance.

How can we reduce earthworks volumes in cut and fill operations?

Generally, the volume of soil to be moved in a cut and fill operation is defined by the topography of the existing ground and the required formation levels for the works. However, it is possible to influence the volumes by design.

Embankment foundations over weak soils

Where embankments are to be constructed over very weak soil deposits, traditionally, the weak soil is excavated and removed from the site as spoil. This is expensive and time consuming. It also requires additional fill material to backfill the volume of spoil removed. An alternative is to utilise embankment foundation systems to enable the embankment to be constructed directly over the weak soil. The TensarTech Stratum foundation mattress system is one such system. It allows construction to take place over extremely weak soils and can reduce overall settlement.

Steep reinforced soil slopes

The side slopes of embankments can be steepened using reinforced soil slope methods. This has the effect of reducing both the required fill volume and the embankment width, saving on land take. TensarTech NaturalGreen is suitable for increasing slope angles up to 45°, while TensarTech GreenSlope can increase slope angles up to 70°. Both of these systems can incorporate vegetation on the slope surface to blend into the natural environment.

At Eastwood Health and Care Centre, Morgan Sindall used the TensarTech GreenSlope system to construct a 250 m long, 3 m high environmental berm with side slopes at a steep 70° angle. This approach significantly reduced the volume of fill required and eliminated the need for imported material, as all fill was sourced on-site. Transportation costs were minimised and project costs were reduced by utilising on-site materials to create a natural, vegetated finish.

Steep reinforced slopes in the Eastwood Health and Care Centre project reduced fill volume, enabling balanced earthworks using site-won material.

Steep reinforced slopes in the Eastwood Health and Care Centre project reduced fill volume, enabling balanced earthworks using site-won material.

Cut and fill case study: Robroyston Link Road

The new Robroyston Link Road, connecting Robroyston railway station to the M80, crossed an area of weak ground containing extensive peat pockets. While piled foundations were considered, they proved too expensive, and alternative methods like deep soil mixing and chemical stabilisation posed time constraints and risks of groundwater contamination. As an alternative, a TensarTech Stratum cellular foundation mattress was installed over the weak soils to support the embankment. Overall, a total of £0.5m was saved using this technique, compared to using a deep soil mixing solution – all while reducing differential settlement of the embankment.

Installation of the TensarTech Stratum foundation system on the Robroyston Link Road project avoided the need to excavate weak soil and was cheaper than the alternatives of piling or deep ground mixing.

Installation of the TensarTech Stratum foundation system on the Robroyston Link Road project avoided the need to excavate weak soil and was cheaper than the alternatives of piling or deep ground mixing.

How Tensar can help with cut and fill excavation on your next project

This guide has discussed the fundamentals of cut and fill excavation, including the process, its benefits and how to calculate the volumes accurately. We’ve also explored the common issues you may encounter and how to overcome them.

If you have an upcoming project that could make use of cut and fill excavation, get in touch with Tensar’s design team. We’ll produce a complimentary “Application Suggestion” to show how we can help you make cost and time savings.