Enabling Works: Meaning & Construction Process

Date: September 03, 2025

Enabling works are an essential first step of any construction project, ensuring it’s ready for the main construction phase. The site is prepared by addressing any potential obstacles, removing vegetation and debris, clearing existing structures, managing drainage and utilities and stabilising weak or variable soils. By completing these activities, a solid foundation is created, allowing for further construction to proceed safely and smoothly.

What specific processes do enabling works involve? Uneven terrain may require excavation, while sites with existing buildings may need demolition before the next construction phase can take place. This not only helps to prepare the ground but also identifies any potential risks early on. Failure to carry out enabling works can result in significant site delays and increased costs. If this stage isn’t done properly, it can also cause problems later in the project, potentially resulting in differential settlement and infrastructure failure.

This article will uncover what enabling works are, their role in the construction process and considerations before you begin the main build phase. We’ll also explore the various types of enabling works and their benefits, before delving into the challenges associated with enabling works and how to overcome them.

Looking for something in particular? Use the links below to navigate straight to it:

- What are enabling works?

- Types of enabling works

- How carefully planned enabling works benefit your projects

- Considerations before starting enabling works

- Enabling works construction process

- Challenges associated with enabling works

- Enabling works case study: Project Oak Spirax Sarco Ltd.

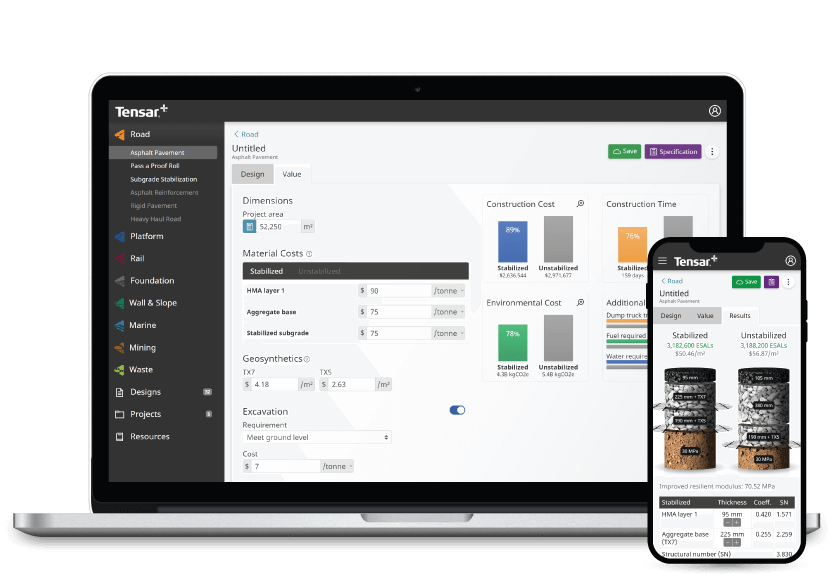

Need support with planning the enabling works for your next development? Reduce costs and ensure long-term performance with our free software Tensar+. To discuss how Tensar can help you deliver better value on your next project, get in touch today.

What are enabling works?

Enabling works in construction are the initial steps taken on a site before the main construction phase begins. These works ensure the site is durable enough to support the planned development or infrastructure. Proper site investigation and preparation allow the construction phase to proceed safely and smoothly.

By identifying any potential issues early on in the construction process, delays can be minimised and costs can be reduced. Early intervention can also help maintain long-term stability and design life of the site while reducing structural and ground-related issues. Enabling works include site preparation tasks, such as temporary access, roads, site clearance, capping layers and soil stabilisation to create a stable platform.

Enabling works vs. groundworks

Enabling works and groundworks involve preparing and working with the site’s ground, but they serve distinct roles in the construction process:

Enabling works prepare a site for construction, addressing any issues such as vegetation, weak and variable soils and existing structures. This phase often involves site clearance, temporary access roads, soil stabilisation and capping layers.

In contrast, groundworks focus on the actual construction of foundations and structural elements. This includes excavation, trenching, piling and drainage installation.

The process begins with enabling works first, creating a stable site in preparation for the groundworks to proceed safely and efficiently.

Types of enabling works

From preparing the ground to clearing the existing structure, enabling works are carried out to create a safe and efficient working environment, ready for the next stage of the development. Below, we will explore the main types of enabling works and their roles in setting the foundation.

Demolition and site clearance

Demolition is the process of dismantling and removal of an existing structure, while site clearance involves the removal of any vegetation, trees and debris. This can also include the removal of any hazardous materials, such as contaminated topsoil. Both processes are essential types of enabling works, as they create a level and clean surface for a new construction project, making it ready for the next phase – improving site access for heavy vehicles to ensure the next phase can begin without any delays.

Utility diversion

It’s critical that you manage any existing utilities found on the site, such as water, gas, electricity and telecommunications. Utilities infrastructure may need to be relocated, diverted, protected, or temporarily disconnected before any construction work begins to prevent the risk of any accidental damage or disruptions . Failure to complete this crucial work can result in regulatory penalties and increased costs.

Ground stabilisation

Focusing on improving any weak or variable soils, ground stabilisation creates a reliable base for construction sites. Without this crucial process, poor ground conditions could affect the stability of new structures and the safe use of heavy machinery and trucks. This type of enabling work often involves the use of mechanically stabilised layers (MSL) using geogrids, which help to distribute loads more evenly and enhance the soil bearing capacity.

Ground stabilisation using Tensar geogrid

Ground stabilisation using Tensar geogrid

Temporary access roads

Two of the most important types of enabling works are temporary access roads and working platforms – creating a safe working environment for all construction vehicles and equipment. Without using temporary unpaved roads, it could lead to issues such as soil compaction and rutting of the subgrade. Access roads and platforms protect the underlying soils while ensuring they can support the load-bearing capacity of the site traffic.

Stabilised access road incorporating Tensar geocomposite and geogrid layers

Stabilised access road incorporating Tensar geocomposite and geogrid layers

How carefully planned enabling works benefit your projects

Enabling works ensure that the construction phase can proceed efficiently and to specification, but with the right approach, they can also reduce project costs, timelines, and carbon emissions. Below, we take a closer look at how carefully planned enabling works can benefit your construction project.

Reduced costs

While enabling works involve upfront expenses, they can create significant savings in the long run. Investing in proper site preparation reduces the need for costly reworks and maintenance later in the project. For example, stabilising weak soils or constructing working platforms can prevent settlement issues and even structural failures. By addressing any issues early, unexpected costs are minimised down the line and the project can remain within budget.

The Green Park Primary Academy in King’s Lynn, Norfolk, needed ground improvement below the car park and site compound at the start of construction. This was due to underlying peat and clay soils that were weak and highly variable. There was also need for working platforms to support piling rigs for the main buildings. Tensar’s T-Value method was used to produce the designs for the working platforms based on rig loadings, soil conditions, and granular fill grading. The two platforms were mechanically stabilised by Tensar geogrids. Overall the project saved 35% in construction costs.

The Green Park Primary Academy saved 35% in construction costs by mechanically stabilising weak and variable clay soils with Tensar geogrids.

The Green Park Primary Academy saved 35% in construction costs by mechanically stabilising weak and variable clay soils with Tensar geogrids.

Improved site safety

Physical hazards, such as unstable grounds, debris, and infrastructure, should be removed as part of enabling works. This creates a safer work environment and ensures all site hazards are addressed before any construction begins – reducing the risk of accidents.

Better site access

Establishing better site access during enabling works ensures machinery and materials can be moved around the site efficiently. This can also prevent heavy machinery and vehicles from damaging the ground. Clear and well-planned access routes can save both time and money on repairs and maintenance works. Construction teams can also coordinate their work more effectively without delays from poor site access. It improves logistics planning and prevents setbacks that could slow down the construction process.

Faster project completion

Enabling works can help to speed up project completion dates by resolving any issues before the main construction begins – helping avoid unplanned project pauses and delays. This includes addressing highly variable and unstable ground conditions. Clearing the site, relocating any utilities and creating access routes can allow construction to begin without any setbacks. Planning in advance can make sure the project continues to stick to the schedule more efficiently, making the deadlines more achievable.

North Heybridge Estate Road faced the issue of low-strength subgrade soils across the site. The pavement design that was to be built needed to achieve a Foundation Class 1 as required by Essex County Council’s specification from CD225: Design for New Pavement Foundations. Tensar used a mechanically stabilised layer (MSL) and incorporated Tensar InterAx geogrids to cap over low-strength soils and achieve the pavement specification. Overall, the project minimised granular fill quantities as well as project excavation. It also reduced transportation activities and saved a total of 12 days (50%) of construction time.

North Heybridge Estate Road saved an estimated 12 days (50%) in construction time by incorporating a Tensar InterAx geogrid in low-strength subgrade soils.

North Heybridge Estate Road saved an estimated 12 days (50%) in construction time by incorporating a Tensar InterAx geogrid in low-strength subgrade soils.

Reduced waste

Proper site preparation can significantly reduce the amount of waste by reusing and repurposing materials during the demolition, site clearance and excavation stages on the construction site. Whether it’s from site-won or recycled aggregates, these materials can be applied to various applications, such as road bases, working platforms and fill layers. Not only can this reduce the volume of waste sent to landfill, but it also reduces disposal costs.

Using recycled materials obtained from site clearance can also minimise the need for sourcing new materials, helping to lower the embodied carbon associated with construction. This contributes to better sustainable construction practices – minimising the project's overall environmental footprint and promoting better resource management on the site.

Considerations before starting enabling works

Before beginning enabling works, careful planning is essential – especially as it lays the base for the main construction phase. Without preparation, the enabling works could lead to unexpected costs, project delays and even safety issues. In this section, we will explore everything you should consider before beginning any enabling works to maximise their efficiency.

Timeline planning

Creating a detailed timeline is crucial for enabling works. It should cover every stage, from initial site assessments and surveys to site clearance and potential ground improvements. Scheduling realistic timelines for each stage of the enabling works process can ensure the project remains efficient. Advanced planning also helps spot potential site issues early and allows for adjustments in the schedule to address them.

However, sometimes not everything goes according to plan. Unexpected conditions, such as poor weather and weak or variable soils, can cause delays. It’s important to build in buffer time within the schedule and overcompensate task durations in case these issues emerge. With a well-planned timeline, the project can remain on schedule while reducing the risk of costly delays.

Regulatory requirements

Enabling works have to meet strict regulatory requirements. This can vary based on the location, project type and any environmental sensitivity to the site. Approvals may include planning permissions, demolition licences, traffic management with any road closures and environmental protection. It’s important to identify regulatory requirements early on in the pre-construction process to avoid potential delays – even resulting in project shutdowns and penalties. If you’re working on a site with environmental regulations, it’s crucial to do this before construction, particularly regarding waste management and the site's environmental impact.

Budget

The initial cost of enabling works can be significant, so the budget you decide needs to be both realistic and account for any unexpected issues. This means planning for all expected costs, including surveys, demolition, site clearance, temporary access roads and soil stabilisation – all while including a contingency for any unforeseen issues. Once the enabling works begin, having a buffer for any hidden discoveries, such as unexpected ground conditions, ensures that you’re covered.

While it can be tempting to restrict costs, underfunding enabling works could make it more costly later down the line. Without proper budgeting, enabling works could result in delays, potential redesigns, or being more expensive than originally planned. Viewing enabling works as an essential investment can extend the design life and deliver long-term savings – all while improving the overall project value.

Site conditions

Before any enabling works begin, it’s key to fully understand the site’s current conditions. Soil type, ground stability and drainage should be explored through topographical and geotechnical investigations to identify any risks. This could result in design changes and amendments to accommodate the existing ground conditions. Proper evaluation at the beginning of the process can reduce any unforeseen issues from arising and ensure the project continues efficiently.

Enabling works construction process

As the essential first stage to preparing a site, enabling works for its main construction activities, enabling works ensure the area is safe and accessible. It creates a smooth and efficient transition into the core construction phase. We will explore the enabling works construction process and how it sets you up for a successful project delivery.

Site assessment

The construction process begins with a site assessment to determine the project’s starting condition. It involves evaluating the land’s current conditions, including soil types, the site’s current terrain, drainage and any existing vegetation. If the site has any heritage features or is within a protected habitat, these must be identified and considered to remain compliant with regulations.

Surveying and investigation

After the initial site assessment is complete, the next stage focuses on undertaking detailed surveys and investigations. This helps to map out the physical and environmental conditions of where the enabling works will take place. Topographical surveys are used to record ground levels, gradients and boundaries – helping design teams understand if the land needs levelling through cut and fill excavation. Utility mapping is also used at this stage to locate any water, gas, or electricity so they can be removed and relocated before construction works begin. The ground itself will need to be tested to ensure it can support the planned infrastructure later down the line. Surveys include checking the California Bearing Ratio (CBR) to measure how much weight the ground can support, as well as the soil’s shear strength to determine the bearing capacity.

Construction

Once all the assessments, surveys and permissions are complete, the enabling works can begin. Construction begins with clearing any vegetation and debris, along with the disposal of any waste material. Some materials may be reused and utilised on site – minimising waste and the need for more resources. Not only does this contribute to more sustainable construction methods, but it can save time and money, too.

The ground may need to be levelled to create a stable base. If any weak or variable soils have been identified on the site, subgrade stabilisation will be required to improve the bearing capacity. Tensar InterAx geogrids can be used to create a mechanically stabilised layer over weak soils to distribute the load to the subgrades more evenly, ensuring it can carry the weight of the machinery and planned structure – preventing differential settlement while providing a reliable foundation.

Our geotechnical design software Tensar+, can help plan and optimise enabling works while helping you to create a smooth and durable surface for construction. Contact us to learn more about how we can support your next project.

Get in touch for a free consultation

Monitoring post-construction

After the enabling works are complete, the site will need to be monitored to ensure it meets all safety and quality standards. While any issues should have been identified in the early stages of enabling works, maintenance checks can ensure there are no differential settlement issues. Inspecting the area can help uncover any minor issues before they escalate into bigger problems. This final stage of the enabling works process is key to ensuring the site remains safe and prepared for the main construction phase.

Challenges associated with enabling works

While enabling works are critical for preparing a construction site, they can come with their own set of challenges. Read on to explore the main obstacles to enabling works and what you can consider to overcome them.

Unexpected ground conditions

Even with site investigations and careful planning before construction begins, unexpected ground conditions may arise once enabling works are underway. If weak or highly variable soils are found in the process, a redesign may be required, along with further site investigations. In many cases, further soil stabilisation techniques may be implemented to ensure the site can support the main construction project. If these issues are not properly addressed, they could lead to differential settlement and even structural instability. Tensar geogrids and a mechanically stabilised layer (MSL) can be incorporated to provide effective reinforcement – enhancing the soil performance and improving the load-bearing capacity.

Budget overruns

A common challenge during enabling works is budget overruns. This can be due to unforeseen site conditions, material imports and revised design requirements. Extended timelines from these issues, along with the requirement of additional materials, can increase the costs rapidly. While enabling works are expensive, they are a necessity. Without a solid base, the next phase of the construction project could be compromised. Regular budget reviews and reusing site-won materials where possible can keep the expenses down.

The Axbridge Road project required the provision of a capping layer over weak ground and the accommodation of construction traffic. The capping layer was required to reduce the thickness of aggregate while achieving a surface modulus of 50MPa (5% CBR), equivalent to a foundation class 1 in CD225. Originally, the design for the Tensar mechanically stabilised layer (MSL) included two layers of geogrid to support the poor ground. A re-design using Tensar InterAx was required, allowing a single layer of geogrid to be used – reducing the overall thickness of the capping layer while maintaining performance. Overall, an estimated construction cost reduction of £86,000 (28%), highlighting how careful design can minimise budget overruns.

The Axbirdge Road project saved an estimated £86,000 in construction costs by using Tensar InterAx geogrids as a capping layer over weak ground.

The Axbirdge Road project saved an estimated £86,000 in construction costs by using Tensar InterAx geogrids as a capping layer over weak ground.

Planning and regulatory delays

Delays are a regular occurrence in enabling works, often due to planning and regulatory requirements. Planning permissions and regulatory approvals can create delays in project timelines if they aren’t properly managed. These setbacks usually occur due to incomplete documentation or when more complex assessments are required. Planning in advance and being proactive with scheduling extra time in case delays arise can ensure projects stay on track. Remaining compliant can also prevent costly legal and financial penalties.

Using Tensar+ can support the design of enabling works, helping to streamline project plans and keep the project on track – all while ensuring full compliance with regulatory requirements.

Environmental impact

While crucial in the construction process, enabling works can cause a negative impact on the environment, potentially causing damage to local habitats, soil disruption and an increased amount of carbon emissions. One of the main reasons it can affect the environment is from the frequent handling, transportation and disposal of materials. Poor waste management and not making use of materials on site can further impact this.

Phase one of the Owenniny Windfarm project involved building unpaved access roads and temporary working platforms at 29 wind turbine locations. The wind farm was constructed on challenging grounds, which now needed to support heavy construction traffic. Tensar’s mechanically stabilised layers and geogrids maximised the performance of the working platforms and access roads. 50% less imported fill was required, along with a 50% reduction in CO2 emissions.

The Owenniny Windfarm project reduced its carbon emissions by 50% and required 50% less imported fill by using Tensar geogrids on the site's soft ground.

The Owenniny Windfarm project reduced its carbon emissions by 50% and required 50% less imported fill by using Tensar geogrids on the site's soft ground.

Enabling works case study: Project Oak Spirax Sarco Ltd.

The Project Oak Spirax Sarco Ltd. project involved a new building with a basement to be constructed on soft alluvial clay with a high groundwater level. With poor ground conditions and a high water table, the main challenge was to minimise the depth of excavation for the pile mat. Due to the low-strength subgrade soils outside the scope of BR470, an alternative method was required to allow piling operations to safely take place.

Tensar’s alternative to the BR470 approach, the T-Value method, was used to determine a mechanically stabilised working platform thickness, incorporated with Tensar InterAx geogrids. This prepared the site and successfully created an outcome of reduced platform thickness despite extremely challenging ground conditions. It also helped the project team continue the enabling works with Tensar’s design support while resulting in a technically and commercially viable solution.

The Project Oak Spirax Sarco Ltd. project reduced excavation depth and enabled safe piling on soft, waterlogged ground by using Tensar geogrids and a mechanically stabilised platform.

The Project Oak Spirax Sarco Ltd. project reduced excavation depth and enabled safe piling on soft, waterlogged ground by using Tensar geogrids and a mechanically stabilised platform.

How Tensar reduces the cost and timelines of enabling works

This guide has introduced you to enabling works, explaining its meaning, its different types and the construction process. We’ve also discussed the challenges associated with enabling works and how to overcome them.

Our free Tensar+ software can assist you with planning and optimising your enabling works, providing insights into how we can support your next project. Tensar geogrids incorporated with our mechanically stabilised layers (MSLs) can also improve soil stabilisation, load distributions and minimise any environmental disruption, cutting costs and reducing project timelines.

If you have an upcoming project that could make use of enabling works, get in touch with Tensar’s design team. We’ll produce a complimentary “Application Suggestion” to show how we can help you make cost and time savings.