Embankments: Meaning, Construction, and Applications

Embankments are banks of soil or stone used to create stable, elevated platforms for various applications, such as roads, railways, and airport runways. The primary reason why we would build an embankment is to raise ground levels over low-lying or uneven ground – creating a strong and durable construction base. The majority of embankments are permanent structures, while others are temporary, such as designs to support haul roads or site access routes.

Designing embankments requires careful planning. If you expect heavy traffic loads, the embankment structure must offer sufficient bearing capacity to withstand these. Soil conditions and the local weather can also impact design life. Poorly designed embankments that don’t account for these factors can experience differential settlement, drainage issues, and ultimately failure. Not only will this disrupt the day-to-day usage of the embankment area, but it can also lead to costly repairs and frequent maintenance requirements.

Read on to discover more about exactly what embankments are, the applications they’re used for, and the design and construction process. Along the way, we’ll also explore the key advantages of embankments before considering the challenges associated with embankments and solutions to overcome them.

Looking for something in particular? Use the links below to navigate straight to it:

- What do we mean by embankments?

- What is the purpose of an embankment?

- Advantages of embankments in construction

- Embankment applications

- When to use retaining walls vs slopes for embankments

- The embankment design process

- Embankment construction

- Challenges associated with embankments

- Climate change resilience - Countering the effects of climate change on embankments

- How Tensar can help with constructing stable embankments

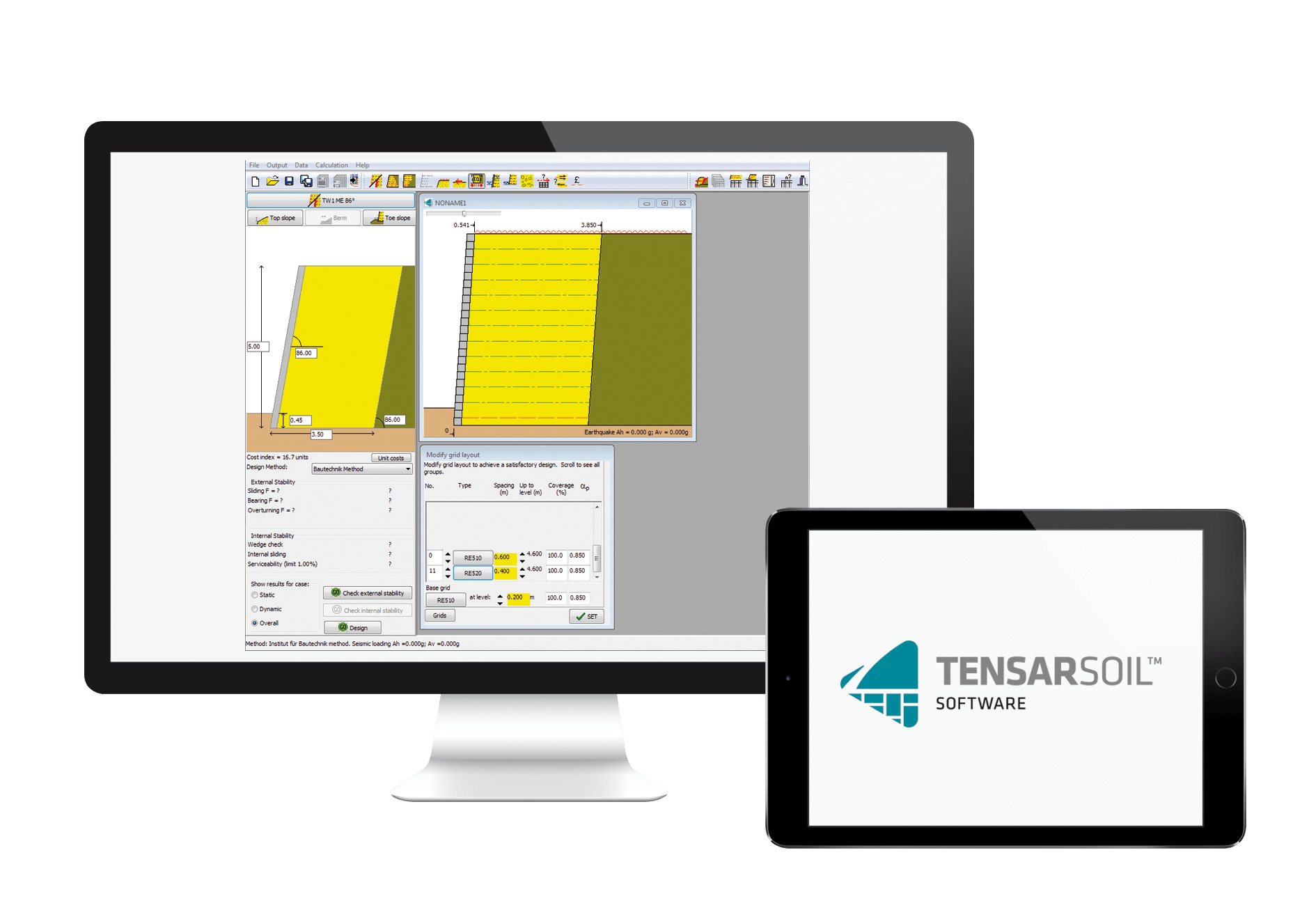

Looking to design an embankment? Reduce fill requirements, improve stability, and cut costs when designing an embankment with our free design software, TensarSoil. To discuss how Tensar can help deliver better value on your next project, get in touch today.

What do we mean by embankments?

An embankment is an earthworks structure in the form of a ridge or mound, raised above the surrounding ground. Typically constructed from soil, aggregate, rocks, or a mixture of these materials. Embankments are commonly required for road and railway infrastructure and other civil engineering works.

An embankment constructed using the TensarTech® NaturalGreen™ Slope System.

Cuttings vs embankments

Modern roads and railway lines are constructed with minimal gradients to maintain transit speeds and maximise transport efficiency. Where routes pass through undulating landscapes, earthworks are necessary to smooth out the vertical alignment. This typically involves constructing embankments to elevate the route above depressions, gullies, and valleys. Through raised areas of the landscape, cuttings, or excavation are necessary to lower the route below original ground level.

Balanced Earthworks

An efficient design will balance the volumes of earth removed from cuttings with that required for embankments over a reasonable length of the route. This minimises the need for import and export of earthworks material from the site and keeps costs down – a desirable outcome referred to as balanced earthworks.

What is the purpose of an embankment?

Embankments have been constructed by man since the stone age. The earliest known example of an earth embankment in the UK was constructed around 3600BC to form a raised boundary on Hambleton Hill, Dorset. Way before that, raised embankments recently discovered in Kazakhstan are believed to date back to 8000BC. Known as the Steppe Geoglyphs, their purpose is yet to be determined.

Modern-day embankments are constructed for a variety of engineering purposes. Building stable embankments over weak ground can be a challenging geotechnical engineering problem.

Elevation of infrastructure

Road and railway construction often include sections of embankment to raise the surface alignment above ground level, in some cases to smooth out the vertical alignment and reduce gradients, but also to raise the road and rail structure on embankments above soft ground or flood levels or to approach a bridge crossing. Airport runways constructed on sloping ground will also require the construction of wide embankments below the airfield to create the shallow surface gradients needed for the operation of aircraft.

Flood protection

Flood protection of low-lying areas can be achieved by the construction of long embankments called dikes or levees. When oil or other liquids are stored in large tanks, steep sided earth embankments surrounding the tanks can protect adjacent areas from leakage or catastrophic tank failure.

Containment

Earth dams constructed to impound water may be constructed as large earth embankments, usually with a clay core to prevent seepage. These structures can range in size, from small dams for agricultural ponds or stormwater retention, to major earth dams for large reservoirs. In Landfill sites, they raise thier capacity by constructing embankments around the perimeter to increase the usable containment volume for waste.

Protection

Fighter aircraft parked in bays adjacent to runways can be protected by steep reinforced soil embankments constructed in a U shape around the perimeter of each bay. Similar protection bunds can be constructed around buildings to shield or contain explosive blast. In mountainous areas, engineers can install embankments below areas susceptible to rockfall to protect people and infrastructure by intercepting boulders and rock rolling downhill.

Barriers

At airports, engineers often build embankments as sound barriers to protect local residents from noise pollution. Noise barrier embankments are also common alongside railways or roads in urban areas, providing both sound and visual barriers for people in nearby residential and commercial developments.

Designing embankments with TensarSoil

Reduce fill requirements, improve stability, and cut costs when designing an embankment with our free design software

Learn More

Advantages of embankments in construction

Are there alternatives to embankments? For some applications, the alternative will be a rigid structure using concrete or steel. A bridge can be used to elevate infrastructure, a concrete structure can be used as a barrier or for containment and protection. While there will be instances where these alternatives are necessary, for most of the applications identified, earth embankments are the most attractive option.

Time saving

Compared to concrete structures, engineers can construct embankments quicker – especially if suitable fill material is available local to the site. With no curing time needed, the speed of construction depends on how many machines are used to transport and compact the fill. In some cases, where the foundation soil is weak or saturated, the rate of embankment construction is limited by the foundation conditions. In these cases, using a Tensar foundation solution may be used to increase stability and accelerate construction.

Cost-effective

Where fill is available locally, the cost of embankment construction is considerably lower than the alternative of concrete structures. Using stabilisation and reinforcement methods can minimise the amount of imported fill required, while adding more stability to the embankment – preventing the need for as many maintenance costs.

A Robroyston Link Road connecting to Robroyston railway station from the M80 and a residential scheme was required – all while crossing weak ground, including large peak pockets. The area needed to reduce the differential settlement of the embankment. Tensar used its TensarTech Stratum cellular foundation mattress system for the 580mm embankment. The 1.3m thick mattress comprised a TriAx geogrid and uniaxial geogrid walls to improve stability and reduce differential settlement, leading to the project saving £0.5m instead of using a deep soil mixing solution.

£0.5m was saved from using the TensarTech stratum cellular foundation mattress system to reduce differential settlement over weak grounds as part of the Robroyston Link Road project.

Lower carbon emissions

The construction carbon cost will be directly related to the haul distance of any imported fill. Where local fill material is available, the carbon cost is likely to be low compared to concrete structures. The total volume of imported fill can be reduced by the use of embankment foundation systems and by the use of steeper side slopes.

This approach can help lower embodied carbon levels – the carbon footprint of the embankment throughout its entire lifecycle. It’s important to consider the post-construction of the embankment and how much maintenance will be required to ensure it still maintains its full performance. Implementing sustainable alternatives, such as recycled materials, can lower the overall carbon footprint of the construction of an embankment, combined with Tensar geogrids, reducing the amount of excavation and imported materials required.

Slope stabilisation

The volume of fill required, and the embankment footprint, can be reduced by steepening the embankment side slopes. This approach can minimise the land take and overall width of the embankment, saving valuable usable space. Tensar reinforced soil slope systems enable embankments to be constructed with a side slope up to 70° angle, while still supporting natural vegetation on the slope face.

Ease of construction

The construction of embankments uses conventional earth moving and compaction plant. The fill material is placed and compacted in layers to achieve the required density. Consideration must be given to surface water drainage during construction to avoid erosion damage to the structure and surrounding areas. Subsoil conditions largely dictate the construction rate, and it's essential not to exceed the foundation’s bearing capacity. This may require continual monitoring of pore water pressure in the foundation soil. To speed up construction and control settlement, engineers can use embankment foundation systems like TensarTech Stratum® to improve bearing capacity.

Flexibility and durability

Well designed embankments, with proper erosion control and drainage measures in place, are highly durable structures. They have relatively low maintenance requirements and can be expected to last for centuries. In areas susceptible to settlement, embankments can accommodate limited differential settlement without losing functionality. When settlements become excessive and affect surface alignment, engineers can refurbish the embankment by raising and re-leveling. If an additional road carriageway or rail track is needed, embankments can be widened. The additional land take can be minimised by the use of steepened side slopes using Tensar reinforced slope systems.

Environmentally and Aesthetically Attractive

An attractive feature of embankments is that they can have vegetated surfaces and side slopes. By selecting appropriate vegetation, a more natural-looking structure with good erosion protection capability can be created. Well designed and suitably vegetated embankments can blend into the landscape, while providing excellent habitat for local wildlife and plant life.

Embankment applications

Road construction

Most major roads and highway projects will require the construction of embankments. These will elevate the road surface above flood plains, smooth out the vertical elevation in uneven terrain, and raise the road level to match the height of bridge decks at approaches.

Railway infrastructure

Railway lines are usually constructed on low embankments above the surrounding land to improve drainage and avoid flooding. Higher embankments are required to cross valleys and depressions to maintain the shallow track gradients needed for railways. Embankments may also be constructed on sidelong ground to support and elevate the track as it winds through hilly or mountainous terrain.

Railways are less tolerant of post-construction settlement. Differential settlement along sections of track, or at the interface between embankments and rigid structures, can cause major track alignment problems and reduce train speeds – in some cases, requiring major refurbishment.

Embankment foundation systems can be used in construction to reduce differential settlements. We can incorporate rail trackbed improvement methods using Tensar geogrids into track refurbishment projects to reduce differential settlement, or include them in new designs to stabilise transition zones near rigid structures like culverts and bridges.

Looking to learn more? Read about how Tensar created a smooth foundation transition for the Crewe Green Link. You may also want to take a look at our webinar ‘Reinforcing Rail Earthworks in the face of climate change’.

Tensar TriAx® geogrids were used to reinforce the embankment approaches at Crewe Green Link, ensuring stability and reducing settlement near key structures.

Airport runway design

Airport runways are by necessity wide, straight and with very minimal surface gradients. When constructed over should be constructed on a wide embankment. This creates the required level area and raises the airfield runway construction above the surrounding land to improve drainage and reduce flood risk.

Environmental barriers

Earth embankments make excellent barriers to shield residential and commercial developments from noise arising from adjacent roads, railways, or industrial plants. They can also create an attractive visual barrier to improve the environment and increase property values. Where space is limited, the width of the barrier can be reduced to minimise land-take, by increasing the gradient of the embankment side slopes. This is easily achieved by the use of reinforced soil slopes, which can have a naturally vegetated surface.

Flood embankments

Earth embankments are a traditional means of providing flood protection to low-lying land. There are many thousands of kilometres of flood embankments in place, protecting communities and infrastructure. These are located along watercourses and in coastal areas. Although their primary function is flood defence, embankments also serve an amenity function, providing access and enhancing the environment.

When to use retaining walls vs slopes for embankments

Earth embankments usually have shallow side slopes for slope stability. The base width of the embankment is determined by the required width at the top of the embankment and the safe gradient of the side slopes. The base width and associated land-take can be reduced by steepening the side slopes or replacing the slopes with a vertical retaining wall.

Where space allows, steep reinforced slopes with a vegetated surface provide a more natural appearance and offer the lowest cost option. Slopes of up to 70° gradient can be constructed using Tensar slope systems. In some urban locations, vegetation is not a suitable option, or space may be severely limited. In these instances, a vertical or near vertical earth retaining wall is the better option. There are a number of construction methods available for these walls, the most economical and the fastest method is to use reinforced soil wall construction.

Tensar has several modular block faced earth retaining wall systems available with a variety of aesthetic options for the facing.

A reinforced soil wall constructed with Tensar’s modular block system to retain steep slopes and maximise land use on constrained sites.

The embankment design process

Embankment design should be undertaken by a qualified and suitably experienced geotechnical engineer. The design process involves a detailed geotechnical study of the site and the underlying soil profile. Soil characteristics for the foundation soils and proposed fill material will be defined by laboratory testing. The design will then consider static and dynamic loading conditions, foundation stability, settlement, slope stability, drainage, and erosion.

What role can geosynthetics play in embankment design?

Geosynthetics can be used to address critical aspects of embankment design and construction. Designing with the appropriate geogrids and geotextiles can accelerate construction, improve drainage, increase stability, control settlements, and prevent erosion.

Enable access

In some cases, the foundation soils are so weak and saturated that it is difficult to gain access to the site and for fill material to be transported and compacted. The use of a stabilisation geogrid can enable access for personnel and plant, even over the very worst soils.

Accelerate construction

The embankment loading on the foundation soil must not exceed the bearing capacity of the foundation soil with an appropriate factor of safety applied. Exceeding bearing capacity will result in large settlements and possibly deep failure.

Since pore water pressure rises as embankment loads are applied, the soil must consolidate as water is expelled. As load is applied by embankment construction, the pore pressure increases. The soil consolidates as water is forced out and the pore pressure will slowly reduce until equilibrium is established. Using geosynthetic embankment foundation systems will increase stability against deep failure and reduce differential settlement. This allows embankments to be constructed faster, accelerating foundation soil consolidation and the associated settlement. Geosynthetic wick drains, driven vertically into the foundation soil can provide a shortened drainage path to accelerate pore pressure dissipation.

Reduce differential settlement

Where foundation soils vary in depth or characteristics across the embankment area, the amount of settlement will vary. This can cause stability problems and will affect the embankment surface profile. Differential settlement can be controlled by the use of a stiff cellular foundation mattress system at the base of the embankment.

Provide slope stability

The stability of an embankment slope is influenced by the soil strength and the slope geometry. Where only lower strength fill material is available, or where the slope needs to have a steep gradient, the stability can be improved by the incorporation of geogrid reinforcement, a method known as slope stabilisation. This approach can enable the use of lower quality fill materials, such as mine waste. In some cases, existing embankment slopes can fail. It is possible to reinstate the slope to the original geometry, using the same fill material but with a higher factor of safety against failure, by using slope stabilisation methods and incorporating layers of geogrid within the fill as it is replaced and compacted.

Improve drainage

A horizontal drainage layer of gravel is usually placed at the base of an embankment to allow water to drain laterally and relieve pore pressure in the foundation soil. This can be enhanced by the use of geosynthetic wick drains. A filter/separator geotextile will usually be placed above and below the horizontal drainage layer to prevent contamination of the gravel and maintain transmissivity.

Erosion protection

Newly constructed soil slopes can be susceptible to soil erosion in periods of heavy rainfall. Geosynthetic erosion control mats laid down on the embankment slopes can prevent soil erosion and encourage the establishment of vegetation.

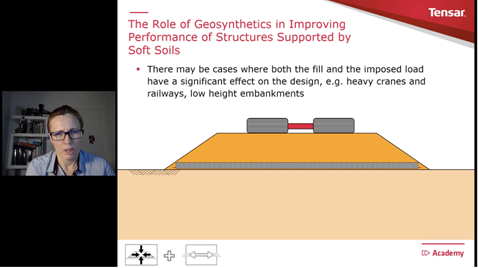

Reinforcing embankments over soft soils using geosynthetics

The use of geosynthetics to enable quick and stable embankment construction over weak soils has been described above. In this video, Dr Kasia Zamara covers the topic of Cost-effective Solutions to Shallow-Embankments over Soft-Soils, exploring the design and construction of embankments. The methods are illustrated by referring to helpful case studies.Dr Zamara also emphasises the sustainability and climate resiliency benefits of embankment foundation systems and geogrid stabilised slopes.

Embankment construction

In the UK, the design and construction of road embankments are subject to the Specification for Highway Works – Series 600 Earthworks, contained in the Manual of Contract Documents for Highways Works (MCDHW). The process is as follows:

- The area below the embankment will be prepared by removing large vegetation, tree stumps, and unsuitable materials. In most cases, topsoil will be stripped for later use.

- You then construct any pipes, culverts, or bridge works required to allow surface water, streams, and rivers to flow across the line of the embankment.

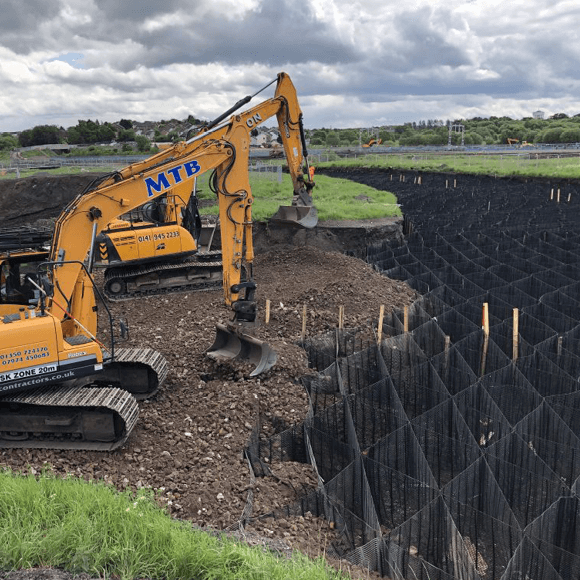

- Any embankment foundation system, such as a cellular foundation mattress or geosynthetic basal reinforcement, piles, or rammed aggregate piers, will be installed.

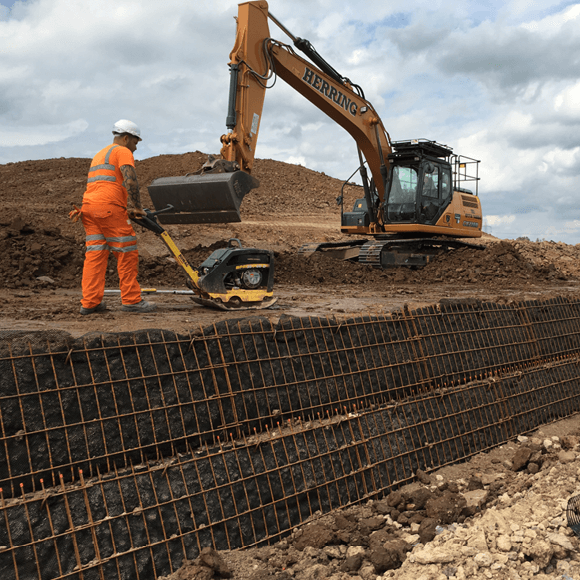

- The embankment construction progresses by the placement and compaction of selected fill material in layers of defined thickness. During this stage, if the slopes are to be stabilised, geogrid reinforcement layers will be incorporated at the specified levels. It is usual to slightly overfill the embankment width to allow for trimming back to a well compacted final profile.

Preparing an embankment foundation using the TensarTech® Stratum® system.

Challenges associated with embankments

While embankments are essential for supporting various infrastructures and flood defences, they present their own set of challenges during and after construction. Read on to explore the key challenges of embankments and what you should consider to overcome these difficulties.

Maintenance requirements

While there is usually no structural maintenance required, it is necessary to ensure that good surface water drainage is maintained to avoid erosion problems. Any pipes or culverts below the structure must be inspected and cleared of any debris. Vegetation may need to be cut back, and larger trees removed. Where slopes show signs of movement, some remedial measures may be needed to improve drainage or increase stability using measures such as the SRT Plate Pile System. Slope failures can be repaired using geogrid reinforced slope repair methods.

Cost

Embankments are major civil engineering works, requiring the transportation and compaction of large volumes of fill material. The cost will be heavily influenced by the proximity of the fill source to the embankment site. Bridges or structures for the elevation of roads and railways are likely to be considerably higher in cost compared to earth embankments and usually require longer to design and construct.

Tensar geogrids can help reduce maintenance costs by extending the application's design life, while reinforcing the embankment and improving its load distribution – minimising the amount of aggregates needed and ultimately the cost.

Risk of differential settlement

Embankments apply a considerable load to foundation soils. This causes consolidation, where pore water is forced out and the foundation soil densifies, resulting in settlement of the embankment. This process occurs during the construction period but may continue for some time post-construction. The magnitude of settlement will vary across the embankment width. Inconsistencies in the foundation soil depth and characteristics will also result in differential settlement. We can controll differential settlement by the use of stiff cellular foundation mattress systems.

Environmental impact

Embankments can have a positive environmental impact by providing a visual barrier and noise barrier around infrastructure and industrial development in sensitive areas. The vegetated slopes of embankments support flora and fauna and provide valuable green corridors to enhance biodiversity. A negative effect might be the interruption to surface and sub-surface water flow that could impact the local hydrology and ecosystem. High embankments can also visually intrude on more open landscapes.

The environmental benefits that can be obtained from the construction of well designed embankments can be seen in this case study from Green Lane, part of Network Rail’s Great Western Mainline project. Where protection was provided to a site of special scientific interest (SSSI) by constructing the embankment using TensarTech® GreenSlope™ System and Tensar Basetex® basal reinforcement geotextile’.

Installing the TensarTech® GreenSlope System as part of the Green Lane Rail project

Climate change resilience - Countering the effects of climate change on embankments

There is no doubt that changes in weather patterns as a result of climate change, will create problems with some existing earth embankments, even those which have been in place for a century or more. It will also force changes in the design of new embankments. Increased rainfall intensity and prolonged drought periods will cause issues with embankment slope stability and surface erosion. For more details on this topic, including some of the solutions, take a look at our webinar, ‘Reinforced Rail Earthworks in the face of climate change.’

How Tensar can help with constructing stable embankments

We have seen how the use of Tensar embankment foundation systems and stabilised slope systems can improve the speed of construction and reduce the cost and environmental impact of embankments. TensarSoil design software is available for engineers wishing to design with these systems. Tensar geogrids can also be applied to embankments to improve the effectiveness of applications such as roads, airport runways, railways, and additional foundation support. Alternatively, Tensar can provide advice or design support specific to your project. Contact us today for a free consultation.