Tensar® Glasstex®

- Glasstex stress absorbing membrane interlayers serves three functions: reinforcement (load transfer), stress relief and waterproofing

- Controls cracking in asphalt to extend pavement life

- One of a range of Tensar asphalt interlayer products – offering the right products for specific problems

- Tensar has over 30 years of experience with asphalt reinforcement products, providing unrivalled expertise and knowledge.

Need an asphalt design for your project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

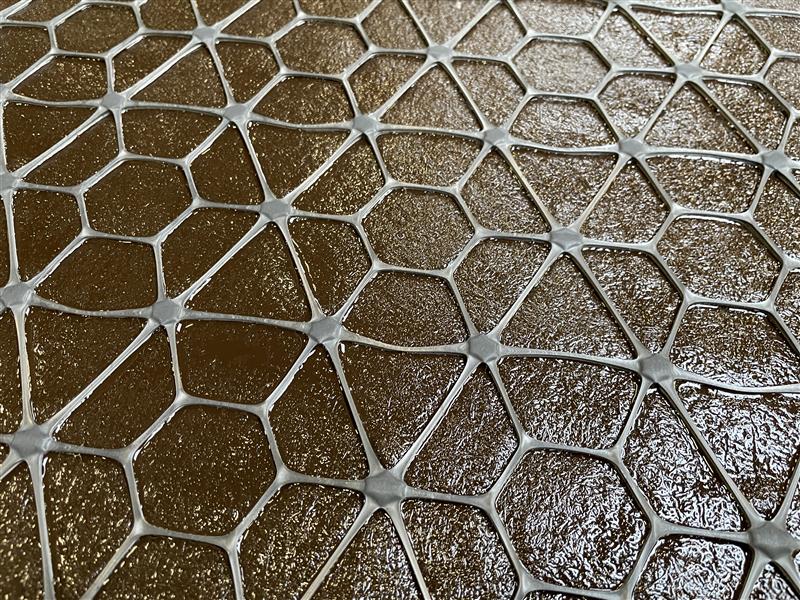

Glasstex is a low-profile composite stress absorbing membrane interlayer product comprising a grid of glass filament bundles, stitch-bonded to a non-woven paving fabric. The high-modulus glass filaments provide high absorption of stress at low strains. After being saturated with bitumen the fabric performs a sealing function. Glasstex provides reinforcement, stress relief and interlayer barrier functions, as defined by EN 15381.

Typically installed under the asphalt binder course, Glasstex’s high-stiffness grid is bonded to the asphalt, providing a reinforcement function by absorbing stress at low strain interlayer levels.

The reinforced stress absorbing membrane layer creates prolonged service life. It controls reflective cracking and mitigates longitudinal cracking caused by differential settlement between new and existing lanes on widened roads

Available in a range of strengths

Glasstex is available in a range of tensile strengths to suit the needs of specific projects:

- Glasstex P50

- Glasstex P100

- Glasstex P200