Asphalt Reinforcement Solutions

Reduce maintenance requirements and enhance the service life of asphalt pavements

Cracking in the asphalt layer reduces the stiffness of the pavement and allows water to ingress. This weakens the foundation layer and subgrade, leading to both further deterioration and permanent loss of strength.

Conventional asphalt reinforcement procedures prescribe placing an additional asphalt grid system overlay on top of the existing surface, or after first planing off the upper asphalt layer (mill and fill). Although this can provide some additional service life, the appearance of cracks is only slowed, and they quickly re-appear from factors like freeze-thaw weathering. With a traditional approach, you will fight a constant battle with pavement maintenance that can never be won.

We offer asphalt reinforcement grid solutions to solve this. With an asphalt interlayer installed, overlay performance is drastically improved, significantly reducing the maintenance cost per kilometre, per year. Tensar offers a family of asphalt reinforcement products that can help, including Glasstex, Glasstex Grid-R, AX5-GN and Glasstex Patch. The Tensar team is always on hand to support you in finding the best fit for your upcoming project.

Need an asphalt design for your project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

What are asphalt interlayers?

Asphalt interlayers are material solutions designed to improve the quality, performance and durability of roads and pavements. An interlayer is placed between two layers of asphalt, preventing (reflective) cracking, moisture ingress, and absorbing stresses.

Tensar has a range of asphalt reinforcement geogrids and interlayers, designed to interact with the bitumen-bound layer. These products add tensile stiffness, limit strains and reduce crack development and size, preventing cracks in the roads and potholes from forming. Composite interlayers comprise a glasstex geogrid bonded to a fabric. Together they provide an asphalt reinforcement and act as a Stress Absorbing Membrane Interlayer (SAMI) and a moisture barrier.

What causes asphalt cracking?

Asphalt cracking can grow from existing cracks or joints in the substrate (reflective cracking). It can also be induced by thermal movement of substrates, or expansion and shrinkage of subsoils. Excessive flexing of the asphalt pavement under traffic loading can also lead to fatigue cracking. For more information, see our guide on types of road cracks and how to avoid them.

How does an asphalt interlayer help?

Reinforcing asphalt interlayers improve pavement life by delaying the onset and propagation of fatigue cracking, saving time and money by avoiding costly road renovation works. They also provide a barrier to moisture ingress while offering stress relief and asphalt reinforcement, to control cracking in the asphalt surfacing. The end result? More cost-effective, long-lasting asphalt roads.

What are the functions of an interlayer?

Asphalt interlayers provide a number of different functions that reduce and prevent cracking:

- A barrier: to prevent the ingress of moisture

- Stress relief: to allow some movement between layers and thus relieve stress build-up

- Reinforcement: to provide tensile strength and stiffness to an asphalt layer.

What are the types of asphalt interlayers?

We offer different types of asphalt products that perform various interlayer functions. If your’re interested in learning the difference between asphalt and tarmac, take a look at our guide on asphalt vs. tarmac.

- Asphalt paving fabrics are designed to absorb bitumen from the installation process, providing a barrier and stress relief functions: There are different forms of paving fabric, with the most common being made from non-woven polypropylene yarn.

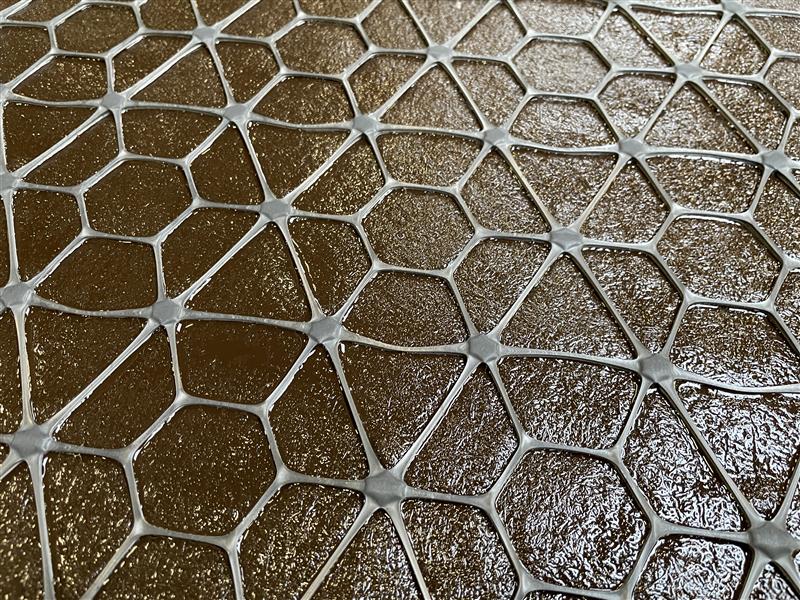

- Asphalt grid interlayers have open apertures to allow the bonding of the overlay to the substrate. The asphalt reinforcement grid structure is typically coated in woven glass fibre.

- Structural grid types have a higher rib profile, enabling interlock between the overlay and the grid. The grid is typically a polypropylene structure with integral junctions.

- Composite interlayers combine a paving fabric with a grid or structural grid to offer multiple functionalities.

How does Tensar compare with the competition?

Tensar's Foundation and Embankment products are proven, high-performance solutions that offer significant benefits over alternative asphalt reinforcement solutions.

.png)

.png)

.png)

.png)