Rail Trackbed Improvement

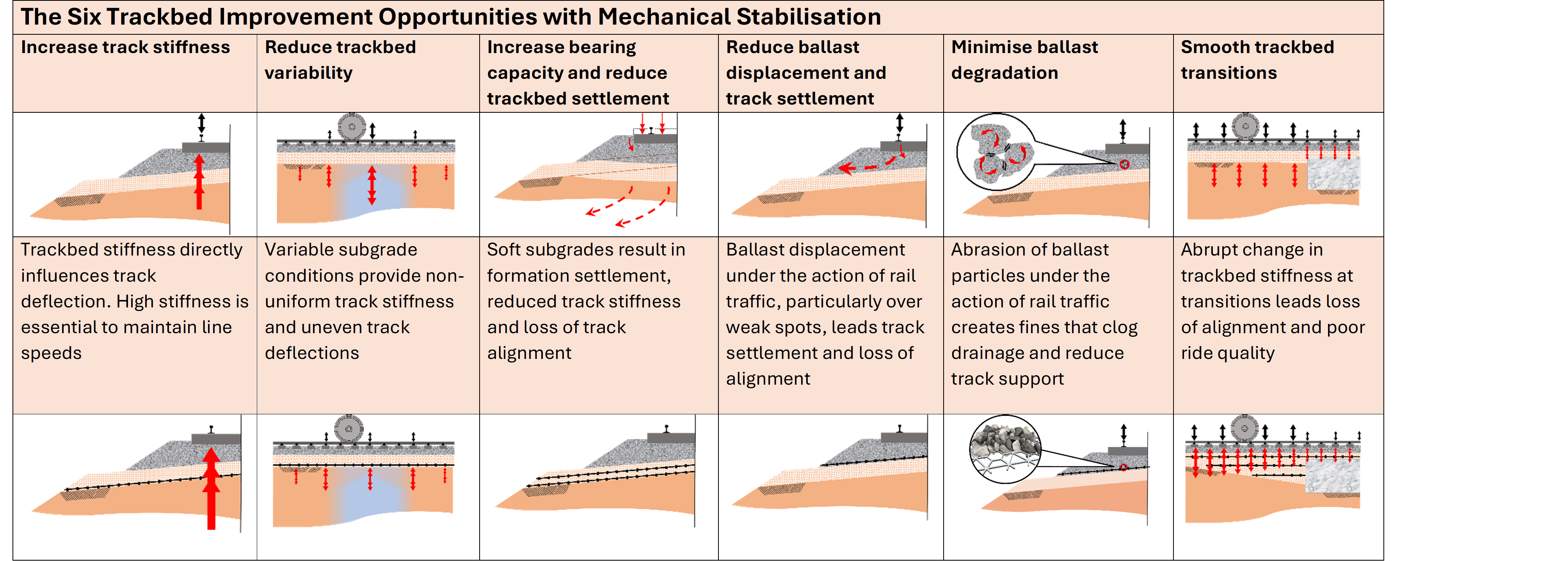

Increase trackbed stiffness, reduce variability, minimise track settlement and reduce ballast degradation.

Tensar railway trackbed stabilisation systems, sometimes mistakenly referred to as rail track reinforcement (see below), are used internationally, delivering track construction and renewal schemes quickly, economically, and safely.

Tensar geogrids have been designed to interlock efficiently with granular materials to provide confinement of the aggregate, thereby limiting movement of the particles under rail traffic load. This reduces deformations and creates a mechanically stabilised layer with improved stiffness and strength.

Railway track reinforcement and rail trackbed stabilisation are terms often used interchangeably when referring to the strengthening of rail trackbed and ballast stabilisation. The correct terminology is trackbed stabilisation as this describes the mechanism by which geogrids strengthen and stiffen the trackbed to increase performance and bearing capacity (see below). Track reinforcement best describes the use of high strength geosynthetics used below rail track for void spanning.

Need a geotechnical design for your rail track stabilisation project?

Tensar’s design team can produce a free-of-charge “Application Suggestion” to illustrate what Tensar’s stabilisation products can achieve and how much value can be added to your project.

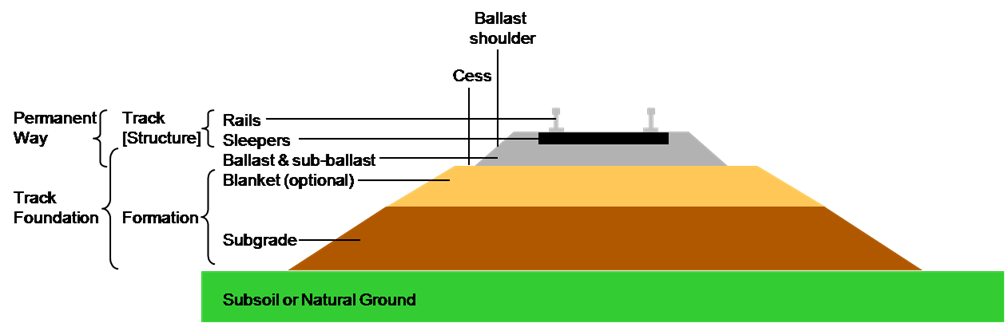

Railway track structure

Railway track construction involves the placement of several layers of material, each performing a different function. Together they provide the necessary support to the track. The terminology can sometimes vary between countries. The illustration shows the terminology used by Network Rail in the UK. The structure is typical for most other countries.

Tensar stabilisation geogrid can be incorporated into the sub-ballast or below the blanket layer to improve bearing capacity and stiffness of the track foundation. Over weak subsoils, Tensar stabilisation geogrid can be incorporated below the formation to enable placement and compaction of the fill material over the soft ground. For extremely weak ground conditions, a Tensartech Stratum cellular foundation mattress can be constructed above the weak subsoil to create a stiff platform on which to construct the track foundation.

The lateral spread of rail ballast is an inevitable consequence of repeated rail traffic. It is accelerated where the track foundation is not stiff enough. Ballast movement can be controlled by incorporating a Tensar stabilisation geogrid. This will usually be installed below the ballast layer during track refurbishment.

Track maintenance

Mechanical stabilisation of ballast - Reduces the rate of track level deterioration

The ability to retain line levels is directly related to the design and condition of the track foundation: when trackbed layers and track formation are adequately designed, only the ballast layer requires maintenance. Periodic tamping is necessary to maintain track levels and compensate for ballast migration under the action of traffic. However,, many sections of existing track have poor track support conditions, resulting in accelerated ballast migration and loss of track quality.

Reduce ballast displacement: Lateral displacement of the ballast under the action of rail traffic, particularly over weak spots, leads to excessive settlement and loss of track alignment. Mechanical stabilisation of the ballast layer controls ballast displacement, maintaining track alignment and extending the period between ballast tamping maintenance.

Minimise ballast degradation: Abrasion of ballast particles under the action of rail traffic creates fines that clog drainage and reduce the ballast layer stiffness. Mechanical stabilisation of the ballast layer limits particle-to-particle movement, reducing degradation and maintaining the ballast layer's strength and drainage characteristics. Learn more about the importance of draining.By incorporating Tensar’s ballast stabilisation geogrid when changing or cleaning the ballast layer, the future migration of ballast is significantly reduced, directly improving the long-term stability of the track. Research shows that track level deterioration can be reduced by up to 2-4 times, translating to tamping maintenance intervals being extended by as much as four times. This means fewer maintenance cycles, reduced downtime, and greater overall efficiency.

Railway track construction

Mechanical stabilisation – Increases trackbed stiffness and strength.

Track stiffness has a major impact on railway track performance. Some deflection under wheel load is a positive thing, as the deflection bowl represents a spreading of load, reducing stresses in each layer. However, excessive deflection causes increased stresses in the rail system and dynamic effects on the ballast layer, leading to loss of track quality.

The stiffness of the trackbed has a major influence on overall track stiffness. Track geometry, deflections and longevity are all influenced by the trackbed stiffness. It is a composite effect of all support layers and is therefore dependent on the properties and thickness of the ballast, sub-ballast, blanket, and subgrade.

Mechanical stabilisation of the sub-ballast, blanket layer or subgrade can increase the bearing capacity and stiffness of the trackbed, particularly over soft, or variable subsoil conditions. Tensar’s railway stabilisation solutions help reduce excessive deflection, maintain track alignment, and ultimately improve the long-term performance of the railway track. This approach helps to optimise the efficiency of rail operations, ensuring a more cost-effective and sustainable infrastructure.

Track renewal & reconstruction

When a rail track has deteriorated, usually due to poor support conditions, it may be necessary to carry out renewal or reconstruction. This will allow drainage issues to be addressed and provides an opportunity to construct a strong, stiff, and durable foundation.

Reduce trackbed variability: Variable subsoil or formation conditions creates non-uniform track stiffness, leading to uneven settlement and track deflections. Mechanical stabilisation of the sub-ballast or subgrade layer reduces the variability of foundation stiffness, providing more consistent track support.

Increase bearing capacity and reduce settlement: Stabilising the sub-ballast, blanket layer or subgrade, improves the bearing capacity of the trackbed, reducing settlement and maintaining track alignment, especially in soft or weak subsoil conditions.

Trackbed transitions

Abrupt changes in trackbed stiffness can occur over below-track structures such as culverts, bridge decks or piled station slabs. This leads to loss of alignment and poor ride quality that limits track speeds. Mechanically stabilised and stiffened foundation approach zones result in smooth transitions.

The track foundation stiffness can be engineered, using mechanical stabilisation techniques, to gradually increase on the approach to buried structures, creating a smooth transition.

Fully validated trackbed design

Tensar has developed a performance-based design method to determine ballast and sub-ballast thickness to prevent bearing failure of the track foundation. It takes account of the projected traffic tonnage to predict subgrade deformation accumulation, ensuring that excess deformation (ballast pocket formation) and progressive failure are unlikely to occur.

A Fully Validated Performance-Based Design

The approach uses cutting-edge 3D finite element analysis (FEA) with advanced hardening plasticity constitutive models to predict permanent deformations in both cohesive and non-cohesive subgrades under train wheel loading.

The benefit of mechanical stabilisation of ballast or sub-ballast layers using Tensar geogrid is incorporated using the Tensar Stabilised Soil constitutive model with input parameters determined from large triaxial compression testing on typical rail ballast and sub-ballast materials with Tensar InterAx and Tensar TriAx geogrids. The results of parametric studies in FEA have been used to develop a simple mobilised bearing capacity approach to performance-based design for rapid optioneering. The design method has been validated by laboratory testing and data from full-scale field trials.

What is railway track stabilisation?

Railway track stabilisation aims at improving the stability and load-bearing capacity of the railway trackbed structure to reduce track settlement and maintain rail alignment. This is crucial for ensuring the safe and efficient operation of trains, especially at higher speeds and with heavy axle loads. It involves the integration of stabilising geogrids, into the ballast or sub-ballast layers to create a stronger, stiffer and more durable track foundation and reduce ballast particle movement.

This is achieved by the mechanism of mechanical stabilisation, whereby the aggregate particles interlock with the geogrid and are confined. The aggregate particles are restrained in both lateral and rotational movement. This stabilisation effect increases bearing capacity of the trackbed and reduces vertical deformation and lateral spread of the sub-ballast and ballast particles. Stabilisation and confinement of the ballast layer reduces particle movement to reduce ballast spread and particle degradation.

‘Rail trackbed stabilisation’ is the technically correct term for this type of solution. You may also hear the phrase ‘railway track reinforcement.’ This actually refers to a separate mechanism for trackbed improvement where a geogrid or high strength geotextile act in tension to provide a reinforcing element, usually below the trackbed. However, the two terms are sometimes wrongly used interchangeably.

Understanding stabilisation vs reinforcement in rail trackbed applications

Railway trackbed stabilisation refers to the structural strengthening of the track foundation using geogrids to improve the mechanical behaviour of the sub-ballast material. Tensar stabilisation geogrids have been designed to interlock efficiently with granular materials providing confinement of the aggregate, thereby limiting lateral and rotational movement of the particles under rail traffic load. This reduces deformations and creates a mechanically stabilised layer with improved stiffness and strength.

Ballast stabilisation with geogrids uses the same mechanical stabilisation mechanism to reduce the lateral movement and rotation of ballast particles. This reduces track settlement due to rail traffic and reduces ballast degradation caused by abrasion.

Railway track reinforcement refers to a different mechanism, whereby a high strength geogrid or geotextile is incorporated into the track foundation, usually below the formation level. Should there be a loss of subgrade support due to excessive deformation or the formation of voids below the trackbed, the reinforcing element deforms and will be put into tension. Provided it is adequately anchored each side of the deformed area, the reinforcing element can then provide support to the trackbed above. This approach may be employed as temporary or permanent protection where there is potential for subsoil collapse due to past mining activities.

Six rail trackbed improvement opportunities with mechanical stabilisation

Better value with Tensar trackbed stabilisation

The quality and durability of the trackbed are critical, both in determining safe operating speeds and in minimising maintenance-related disruption.

Throughout the railway track construction process, including new track and track reconstruction works, the bearing capacity and stiffness of the trackbed foundation can be improved by incorporating Tensar stabilisation geogrids into the sub-ballast layer. In the ballasted track, the time between necessary tamping maintenance can be significantly increased by incorporating Tensar stabilisation geogrid in the base of the ballast layer. Ballast degradation and track settlements are reduced, maintaining track speed and extending maintenance cycles.

For a more in-depth look at the science behind this, head over to our guide on railway geotechnical engineering.