Geogrids provide stabilisation or reinforcement to enhance the performance of soils, as well as separation between soil and aggregate layers. There are four main types of geogrid, each with different physical properties or characteristics. The most suitable type of geogrid in any given application will depend on both these physical properties along with the compatibility of the aggregate and soil.

In this guide, we’ll be looking at the physical properties of geogrids and how they impact suitability, before looking more closely at the key properties of Tensar geogrids in particular.

Use the links below to jump to the section you’re most interested in:

- What is geogrid?

- Types of geogrid

- Geogrid size and aperture

- Geogrid strength

- Ultimate tensile strength

- Junction efficiency

- Radial stiffness

- Elastic modulus

- Long-term design strength

- What are the requirements for a geogrid?

- Physical properties of Tensar geogrids

- Key takeaways

Tensar geogrids can be used to solve civil and geotechnical engineering problems in or on the ground. They help design engineers to achieve substantial time- and cost-savings across a range of applications, from roads and railway trackbeds to working platforms and foundations. If this could be of use for your upcoming project, speak to our team today.

What is geogrid?

Geogrid is a synthetic material used in civil engineering and construction to stabilise soils and aggregates. It is typically made from polymers like polypropylene, polyethene, or polyester, woven or extruded into a grid-like pattern with open spaces.

Enhancing load-bearing capacity, limiting differential settlement, and controlling erosion are the main functions of geogrids, particularly in difficult or soft soil situations. Engineers can also use geogrids to lessen the need for heavy fill and excavation, which lowers project costs and improves environmental sustainability.

Types of geogrid

The physical properties of geogrid vary by design type:

- Uniaxial geogrids: Strong in one primary direction, ideal for reinforcing slopes and retaining walls where support is needed in a single direction.

- Biaxial geogrids: Square or rectangular reinforcement geogrids where tensile strength parameters are important for expected performance.

- Tensar Triax geogrids: These hexagonal stabilisation geogrids improve the performance of granular layers in roads, railways and other trafficked areas.

- Tensar InterAx® geogrids: These are Tensar’s best performing stabilisation geogrids and offer greater project value as part of a road, working platform or other trafficked areas.

Geogrid size and aperture size

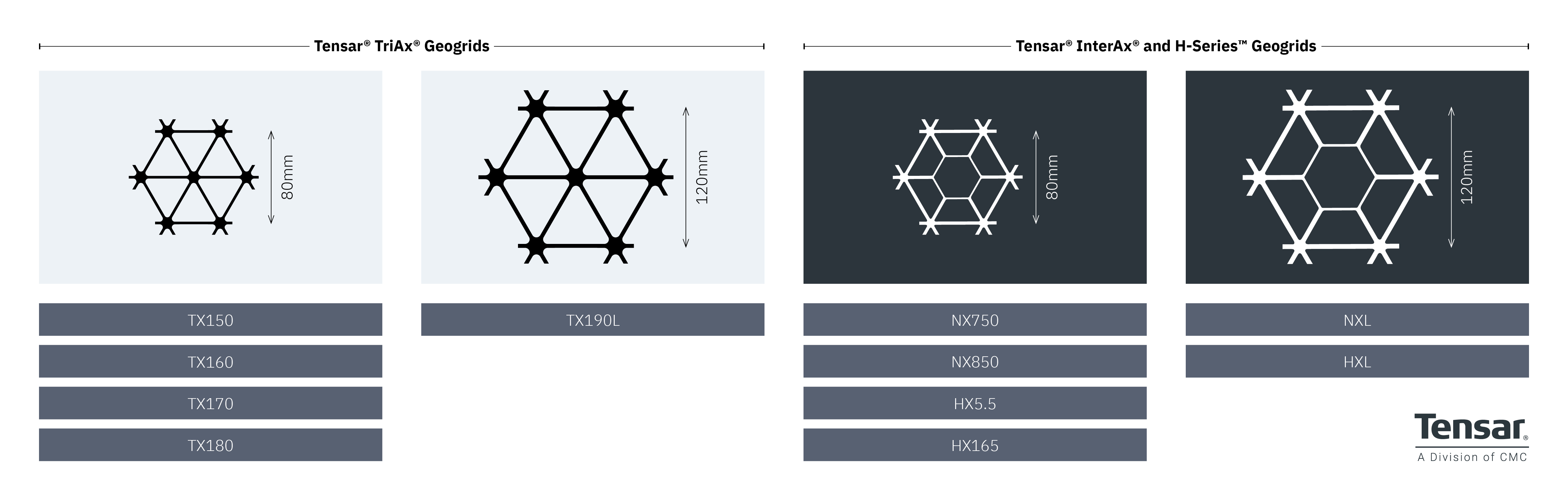

In order to allow interlock and confinement of aggregate to take place effectively, there must be compatibility between the aggregate particle size and geogrid aperture size. For TriAx geogrids, there are different-sized geogrids for a range of fill particle sizes. TriAx geogrids come in three sizes:

- 66mm

- 80mm

- 120mmg

Tensar InterAx, there are different aperture sizes within the single geogrid structure. This provides compatibility with a typical aggregate that comprises a range of particle size.

Tensar geogrid sizes and apertures

Geogrid strength

Geogrid strength can refer to a number of different properties, including:

- Ultimate tensile strength

- Wide-width tensile strength

- Single rib tensile strength

- Long-term design strength

Tensile strength properties of geogrids for the function of reinforcement are important. The physical properties for stabilisation geogrids such as radial stiffness, junction efficiency and rib height are characteristic only and are not used in any design calculations where stabilisation products are adopted. The performance of the resulting road or platform incorporating a geogrid can only be determined based on extensive full scale trafficking and plate load testing of granular layers including the stabilisation geogrid component.

Ultimate tensile strength of geogrids

Ultimate tensile strength (UTS) is the maximum amount of load a geogrid can handle before performance is compromised.

This is established through tensile testing, where the geogrid is stretched until it breaks.

Many geogrid specifications focus on tensile strength, equating high UTS with better performance. In reality, however, UTS is irrelevant, particularly when a geogrid is used in the design of roads or temporary working platforms.

In these cases, the ultimate tensile strength of a geogrid alone is actually a poor indicator of performance. This is because the ‘tensioned membrane’ effect—the strength that a geogrid offer when stretched or strained—does not offer appropriate support for the layers above it.To work, the geogrid has to be stretched. But when a load is placed on it, the geogrid will curve to accommodate this load, similar to what happens when a person sits on a hammock.

Consequently, the pavement will suffer deformation at the level where the reinforcement geogrid is placed. Deformation will also likely appear at the road surface level in the form of rutting, cracks and potholes, reducing its operational life.

Learn more about Why tensile strength is not a good measure of stabilising geogrid performance.

.jpg)

Geogrid junction efficiency

The physical property of geogrids known as junction efficiency is the measure of the strength of the node compared to the strength of the rib, expressed as a percentage and indicates the ability of the geogrid to transfer loads from one rib to other ribs in different directions:

Junction efficiency—and not junction strength—is a parameter the European Assessment Document (EAD) characterises and associates with stabilisation geogrid performance.

The EAD sets out parameters the European Organisation for Technical Assessment (EOTA) confirms are specific to the distinct function of stabilisation. No such link has been made between any junction parameters and reinforcement geogrids.

Junction efficiency vs. tensile strength

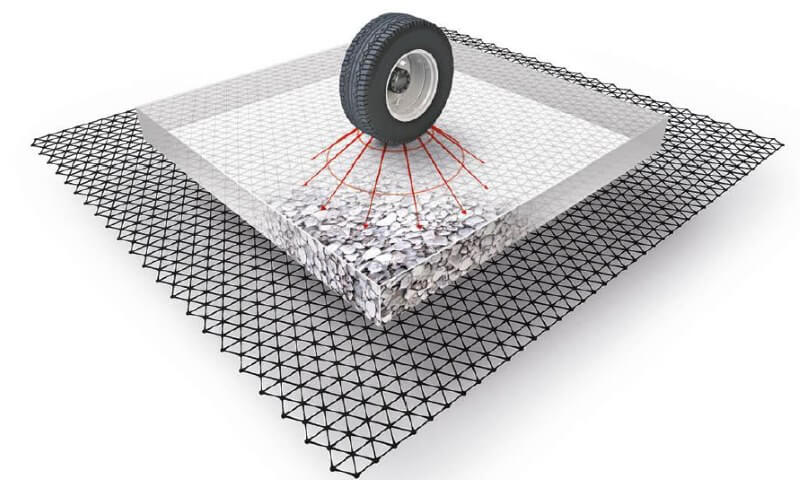

Where stabilisation geogrids are used to take advantage of the ‘confinement effect’, junction efficiency is the more important physical property in relation to performance in road and temporary working platforms than tensile strength.

The confinement effect—where the aggregate is locked into the apertures of the geogrid and pushes up against its ribs, preventing the material from rotating or moving.

Load is put against the ribs, which are held in place by the junctions. As a result, the efficiency of the junctions compared to the rib is one characteristic that will influence the performance of a stabilisation geogrid.

Radial stiffness

Radial stiffness has been identified as a characteristic associated with the distinct stabilisation function of geogrids. Radial stiffness is the mean of stiffness measurements in multiple directions across the geogrid. Radial stiffness ratio can also be determined as an indication of uniformity/isotropy and the ability to respond to a multidirectional load.

Mean radial stiffness and radial stiffness ratio are characteristics of stabilisation geogrids associated with the stabilisation function, with the geogrid acting as a component of a mechanically stabilised layer in road, rail, working platform and other trafficked area. Whilst radial stiffness is one example of a relevant stabilisation characteristic, extensive research must be ensured to demonstrate and quantify the stabilisation performance of a particular geogrid on a particular aggregate material. It is useful to note that the optimised geometry of Tensar InterAx geogrids has shown improved performance over Tensar’s TriAx geogrids, despite the fact that the associated radial stiffness values are lower for InterAx than with TriAx which illustrates the reduced importance of product physical properties in this application.

Elastic modulus

Elastic modulus is another physical property of geogrids related to stiffness, but not related to performance in ‘normal’ applications.

Finite element analysis (FEA) sometimes requires a geogrid’s elastic modulus. However, Tensar’s own research has confirmed that the effect of a geogrid should not be modelled on individual product parameters. We have developed an FEA module—for more information, contact the Tensar Technology team.

Long-term design strength

Long-term design strength (LTDS) is a relevant property of geogrids in reinforced soil applications—including retaining walls and slope reinforcement—where layers of geosynthetic materials (such as geogrids) are placed within the fill used to form the finished structure.

Unlike roads, which bear a constantly changing load, reinforced soil carries a permanent load throughout its operational life, which could be up to 120 years. Consequently, the design of the structure and load-bearing components (including the geogrids) should reflect this.

Factors used to calculate LTDS

Creep strength

Polymers are viscoelastic, meaning their strength and stiffness are affected by temperature and how frequently or long they bear a load. Under a constant load, polymer geogrids will stretch very gradually as their physical properties change.

Creep strength can be assessed by subjecting geogrids to long-term loading. This involves suspending different-sized weights from the geogrid in temperature-controlled conditions and measuring and recording the strain for a standard duration of 10,000 hours, just over a year.

Partial reduction factors

Partial reduction factors—such as environmental effects and the effect of damage caused during installation—should be applied before using creep strength in LTDS calculations.

Uniaxial geogrids are also available in different grades, but their geometry is similar across the range.

Geogrid specifications

For reinforcement applications, such as walls and slopes, specifications may be based on a wall or slope system and should include parameters included as part of the design calculations such as long term design strength and associated factors to take into account the environment the structure is to be constructed – please contact Tensar for specific advice.

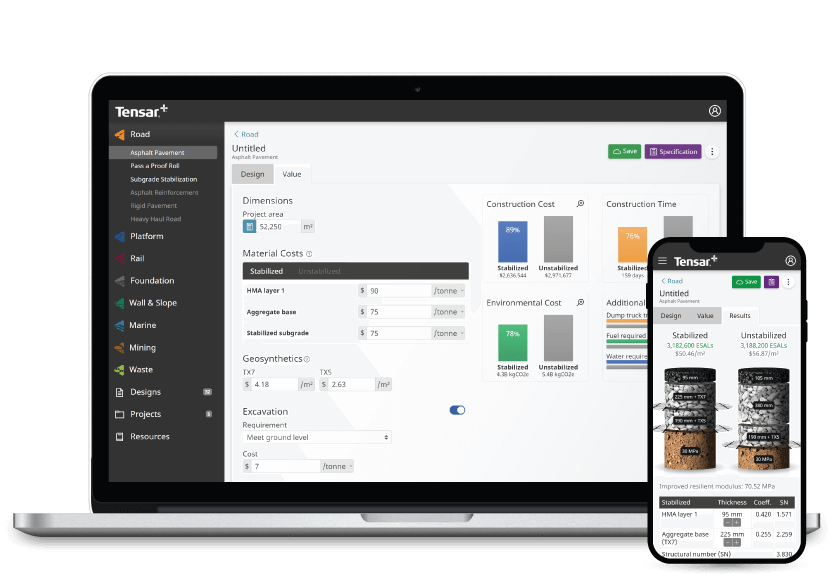

For stabilisation applications, such as roads, platforms and other trafficked areas, the physical properties of the geogrid itself are not included in any design calculations and so are of no use for inclusion in specifications associated with project designs. Tensar have performance-based specifications available and also built into Tensar’s online design software Tensar+ – please contact Tensar for specific advice.

The requirements for a geogrid also depend on its intended application and environmental conditions, such as the project's specific needs and environmental impact. Speak to our team for free advice on your next project.

Physical properties of Tensar geogrids

Tensar supplies a number of geogrid solutions to solve geotechnical engineering problems across several applications. The physical properties of each of these have been outlined below:

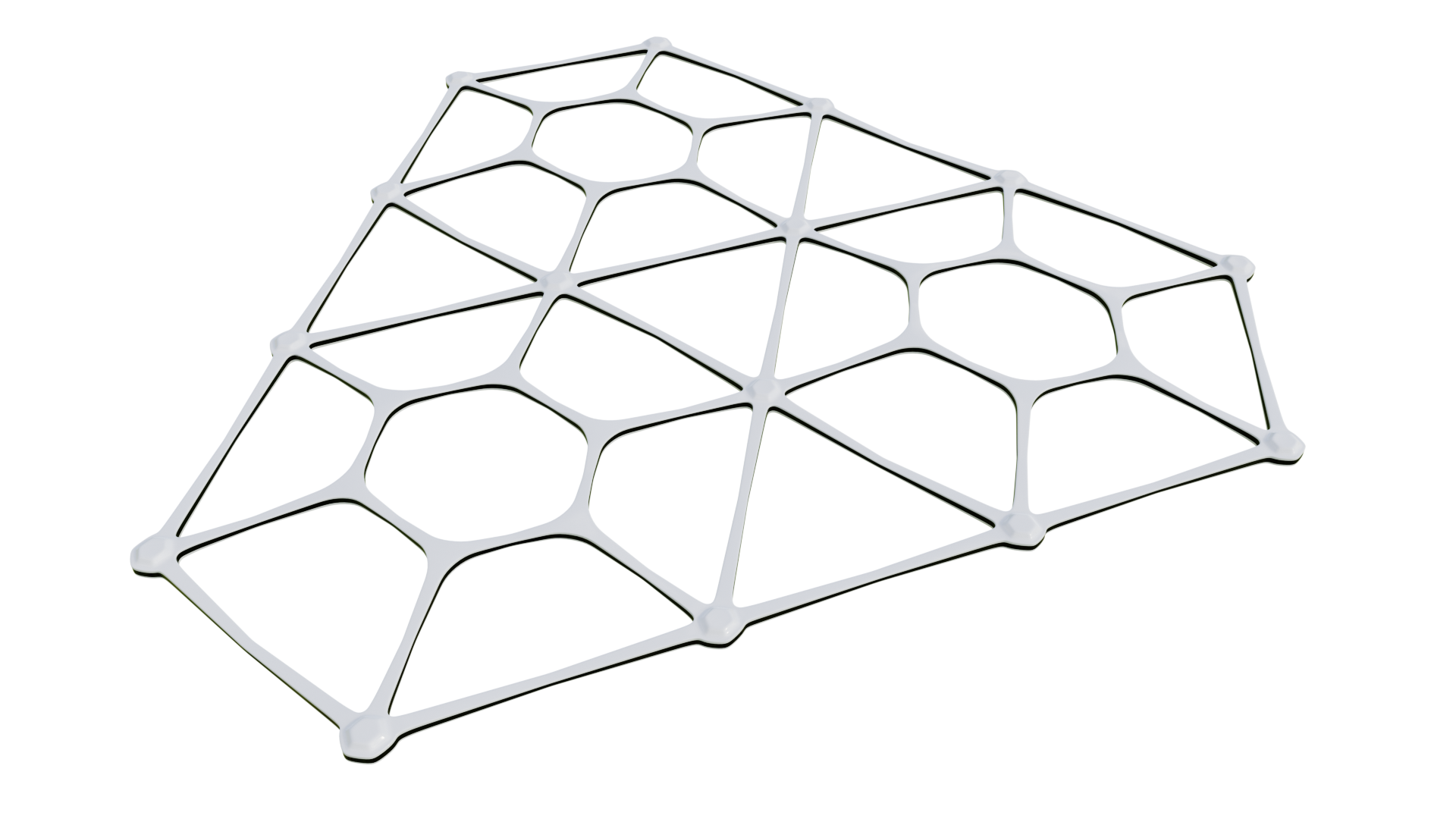

Tensar InterAx® geogrids

- Manufacturing process - coextrusion

- Three different aperture sizes - Triangular, hexagonal & trapezoidal

- Ductile outer layer – improves interlock.

- Complex geometry

- Higher rib aspect ratio

- Elevated inner hexagon

Tensar’s InterAx® geogrids are classified as stabilisation geogrids. The performance, i.e., the effectiveness in stabilising a granular material, cannot be characterised by any single physical property of the geogrid. It is defined only by its stabilisation effect. This is derived from multiple tests conducted on Tensar InterAx geogrid in combination with various aggregate types.

For product identification purposes (not performance-related characteristics), the following physical characteristics may be used:

- Aperture shapes

- Structure

- Rib shape

- Continuous parallel rib pitch

- Rib aspect ratio

- Node thickness

- Colour identification

Tensar® InterAx® geogrids provide the best performance and best value of any other Tenar geogrid. This geogrid material specification includes InterAx® NX750, NX850, NX950, NXL, NX-G, NX-GD and NX-GN.

TriAx geogrids

- Radial stiffness at 0.5%

- Radial stiffness ratio

- Junction efficiency

- Hexagonal pitch

Tensar’s TriAx geogrids are classified as stabilisation geogrids. The properties noted are associated with this distinct function.

Biaxial geogrids

- Ultimate geogrid tensile strength

- Strength at 2% strain

- Strength at 5% strain

- Peak strain

Biaxial geogrids such as Tensar’s SS geogrid are classified as reinforcement products. Geogrid tensile strength and associated strain are properties relevant to this distinct function.

Tensar uniaxial geogrids

- Creep Strength

- Long-term design strength*

- Ultimate tensile strength**

Uniaxial geogrids such as Tensar’s RE geogrid are classified as reinforcement products, specifically for wall and slope applications.

Long-term design strength is based on project-specific conditions. Partial reduction factors should be applied based on variables such as in-soil temperature and installation damage.

**Ultimate tensile strength is not a parameter employed in design calculations but can be used to identify which product is required.

Properties of geogrids: key takeaways

This guide has explained the various physical properties of geogrids and their importance for certain types of applications. The key points are summarised below:

- Physical properties associated with geogrids depend on the intended application.

- Always consider a geogrid’s performance in context as part of an overall system—the benefit is in how the geogrid interacts with the layers around it, not by virtue of its standalone properties.

- Most physical properties of geogrids used in the industry to gauge performance are inappropriate.

- Ultimate geogrid tensile strength is not the most important factor in how well it will perform, particularly in road applications

Design with confidence, from anywhere.

- Design & evaluate pavement and gravel sections

- Design & evaluate working platforms

- Easily compare alternative materials

- Determine initial and lifecycle cost savings, time savings, and sustainability metrics

- Create high-level summaries of the design alternatives for project stakeholders

- Share features that aid collaboration

Next steps

For further information about Tensar geogrids and their physical properties, contact us. If you’ve enjoyed reading this guide and would like to see some other related resources, take a look at: