How Geogrids Make Wind Farm Construction More Sustainable

Date: February 16, 2026

Geogrids are transforming wind farm construction, not only making it more sustainable but also cost-effective. As the UK pushes toward its 2030 net zero goals using renewables, wind energy has become a main contributor, generating over 50% of the nation’s renewable power resources. Yet building these projects often involves carbon-heavy construction work on soft, unstable, or remote terrain. Traditional methods rely on large volumes of aggregates and deep excavation to stabilise access roads and wind turbine foundations.

By reinforcing soil and improving load bearing capacity, geogrids reduce the need for extensive excavation and heavy aggregate use. This not only makes construction faster and safer but also helps lower the overall carbon footprint of a wind farm infrastructure. Projects can be built on challenging sites without compromising performance or durability.

In this guide, we’ll explore where and how geogrids can support wind farm construction, along with where they can be applied across wind energy projects. We’ll also take a look at how they can drive sustainability throughout the supply chain – all while helping reduce the embodied carbon of a wind farm infrastructure.

Looking for something in particular? Use the links below to navigate straight to it:

- How can geogrids support wind farm construction?

- Where can geogrids be used in wind energy projects?

- Sustainability throughout the supply chain

- How geogrids can reduce a wind farm infrastructure's carbon footprint

- Reducing CO2 emissions at Oweninny Wind Farm

- How Tensar can help with your next project

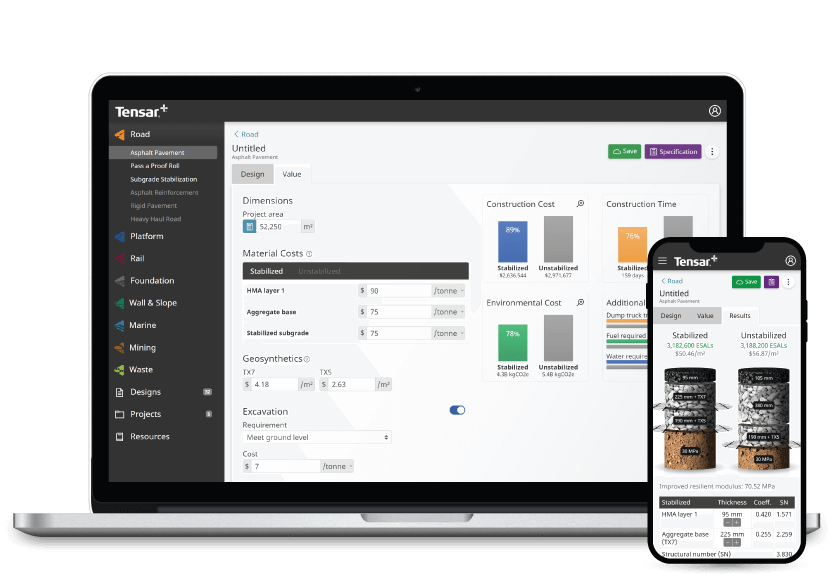

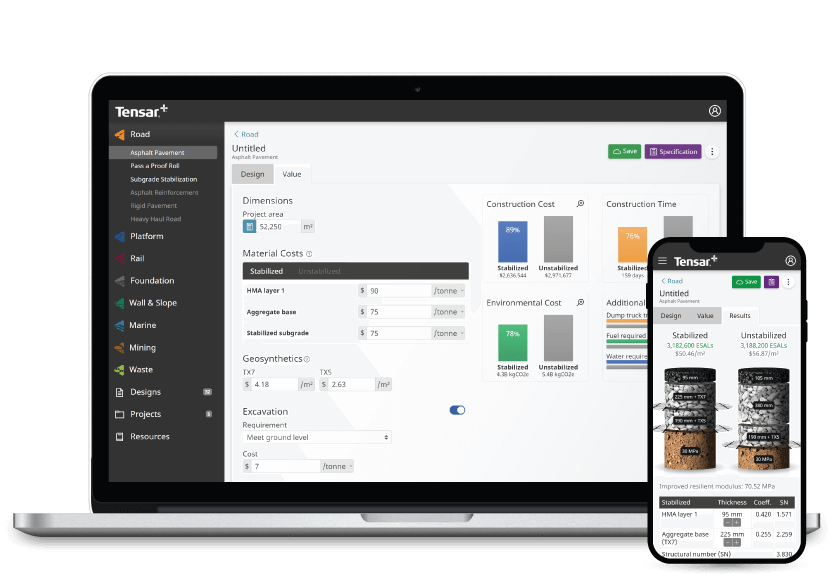

Unlock time and cost savings with our free geotechnical design software, Tensar+, or contact us to discover how we can add value to your next windfarm project.

Get in touch

How can geogrids support wind farm construction?

Geogrids use mechanical stabilisation to interlock with aggregates, creating a stiff composite layer. This spreads heavy loads laterally, increasing the ground's bearing capacity without needing deep excavation or extensive cut-and-fill.

An aggregate layer stabilised with Tensar geogrids performs as a composite, due to the interlocking mechanism and particle confinement that develops between the aggregate and the Tensar stabilisation geogrid. This Tensar mechanically stabilised layer provides more effective support to the entire pavement structure than aggregate alone, improving performance and saving time and money without compromising on safety.

Where can geogrids be used in wind energy projects?

Temporary and permanent unpaved surfaces are a critical aspect of enabling works for renewable energy construction projects. Wind farm sites are often located on challenging terrain, and geogrids are used to ensure stability is created across the entire project footprint. Below, we will explore where geogrids can be used in wind energy projects for both on shore and off shore windfarms.

On shore wind farms:

- Unpaved temporary roads

- Working platforms and crane platforms

- Laydown areas and compounds

- Cable trenching support

- Earth retaining walls and slopes

Off shore windfarms:

- Temporary and permanent access roads

- Crane platforms

- Transformer and substation compounds

- Laydown and assembly areas

- Cable trenching and cable pull roads

Using geogrids in these applications can not only help reduce material use but also enhance the design life and sustainability of the wind farm infrastructure.

Sustainability throughout the supply chain

Sustainability continues to be high on the agenda across industries worldwide, and is a core focus of Wind Europe’s “Industry Principles for Supply Chain Sustainability”.

Here, it states that the industry and its suppliers shall “take a precautionary approach to environmental protection and climate change related to activities, products and services” and also “ensure delivered products incorporate environmental aspects throughout the product lifecycle, from design through manufacturing”.

To support the sustainability agenda, geosynthetics can play a very important part in supporting this during the delivery of temporary and permanent works by helping to deliver the project quickly, economically and safely. Tensar’s drive towards renewable energy and energy efficiency demonstrates how sustainability can be achieved throughout the supply chain. Read on to learn more.

Low carbon manufacturing with 100% reneweable energy

Since 2001, Tensar has been committed to 100% renewable energy. All electricity used by Tensar when manufacturing geogrid products has been certified as coming from 100% renewable sources. The main aim shows Tensar’s commitment to optimising energy and reducing carbon emissions, including embodied carbon. This approach not only supports more sustainable manufacturing but also reinforces Tensar’s leadership in delivering low-carbon solutions to the construction industry.

Zero waste and energy efficiency

In addition to renewable energy, Tensar has made a conscious effort to prioritise efficiency and waste reduction. Intelligent LED lighting has been installed in Tensar’s factory to help support a greener economy. Alongside this, energy-efficient compressors have been fitted to machinery to minimise electricity consumption further. 99.5% of all internal polymer waste is reduced during production – further ensuring resources are used responsibly while minimising environmental impact.

Discover how Tensar could add value to your next renewables construction project. Request a free design assessment or get in touch with our team to find out more.

Get in touch

How geogrids can reduce a wind farm infrastructure's carbon footprint

Wind farm construction often involves moving large volumes of materials, excavating soil, and building access roads over weak and variable ground conditions. However, with the right approach, windfarms can be greener, reducing environmental impact and improving efficiency. Below, we’ll take a closer look at how geogrids can help lower the carbon footprint of wind farm projects.

Cost

Using geogrids can significantly reduce the thickness of aggregate layers, resulting in lower overall material costs. This reduction not only saves money on aggregates, but it also saves the costs of quarrying, transporting, and compaction. Wind farm projects can save on labour, machinery operation and long-term maintenance costs as Tensar geogrids can extend the design life for up to 120 years. Using fewer raw materials can also result in lower embodied carbon emissions.

In the Hagshaw Hill Wind Farm project, contractor Wills Brothers wante d to construct permanent unpaved access roads on a site with low-strength subgrade soils and areas of deep peat. The initial design required using two layers of geogrid; however, the project required lowering the costs. Tensar created a new solution using only one layer of the Tensar H Series geogrid, reducing the aggregate layer thickness. With a 34% overall reduction in aggregate thickness, significant cost savings were achieved throughout the project.

d to construct permanent unpaved access roads on a site with low-strength subgrade soils and areas of deep peat. The initial design required using two layers of geogrid; however, the project required lowering the costs. Tensar created a new solution using only one layer of the Tensar H Series geogrid, reducing the aggregate layer thickness. With a 34% overall reduction in aggregate thickness, significant cost savings were achieved throughout the project.

Time

Construction schedules for wind farms are often limited, and delays can be costly. Geogrids can speed up construction timeframes by improving the strength and stability of existing soils – reducing the need for excavation, backfilling and any extensive aggregate placement.

As wind energy projects can require large volumes of fill, fewer material deliveries can help cut down the need for transportation of large lorries on site while maintaining sufficient bearing capacity. Reducing material use for sustainable construction methods results in fewer vehicle movements. Wind farms can ultimately progress faster, reducing delays caused by access restrictions and site congestion.

The Triton Knoll project initially planned to use a biaxial reinforcement geogrid on saturated ground conditions. However, local sources of aggregates were of poor mechanical strength, resulting in the need to import aggregates over considerable distances. Murphy Group’s main challenge was to limit delivery vehicle movement while avoiding disruption to the local area. Tensar informed Murphy Group that the initial design for the current road thickness would provide insufficient support for the heavy traffic loads. Instead, stabilisation geogrids were proposed. This resulted in a 20-25% reduction in road thickness and 25% savings in carbon emissions from using less imported aggregates.

geogrid on saturated ground conditions. However, local sources of aggregates were of poor mechanical strength, resulting in the need to import aggregates over considerable distances. Murphy Group’s main challenge was to limit delivery vehicle movement while avoiding disruption to the local area. Tensar informed Murphy Group that the initial design for the current road thickness would provide insufficient support for the heavy traffic loads. Instead, stabilisation geogrids were proposed. This resulted in a 20-25% reduction in road thickness and 25% savings in carbon emissions from using less imported aggregates.

Environmentally friendly

In renewable projects like windfarms, sites can be located in peatlands. Usual traditional dig and replace methods can release stored carbon and disturb the local environment. Geogrids can allow for ‘floating road construction’, keeping the peat intact while protecting the ecosystem. By reinforcing the existing ground, geogrids can help prevent erosion – all while providing a more sustainable way to build access roads and the infrastructure.

On the Viking Windfarm in Scotland, most of the site was located on peat and blanket bog. To build and maintain the UK’s largest output onshore wind farm, the construction of an access track and buried cabling was required. Environmental disruption had to be kept to a minimum, so peat removal was limited. Tensar supplied approximately 350,000m2 of geogrid to stabilise the floating roads and support cabling throughout the site. This not only minimised environmental impact due to not excavating the area, but it also protected the peat and limited hydrological disruption.

be kept to a minimum, so peat removal was limited. Tensar supplied approximately 350,000m2 of geogrid to stabilise the floating roads and support cabling throughout the site. This not only minimised environmental impact due to not excavating the area, but it also protected the peat and limited hydrological disruption.

Reduced excavation

By increasing the bearing capacity of the existing ground, geogrids minimise the need to remove poor soils and bring in replacement materials. This can limit the need for excavation, transportation and disposal activities on the wind farm construction site. It also reduced the amount of machinery required on the site, preventing tonnes of wasted aggregates that would otherwise be sent to landfill. Maintaining more of the existing soil structure can also help to improve its long term stability while reducing settlement risks.

Need a Tensar design for your next renewables project?

Our design team are here to help.

Request design assessment

Reducing CO2 emissions at Oweninny Wind Farm

Located in County Mayo, the Oweninny Wind Farm is one of Ireland’s major onshore wind energy developments. Delivered by Oweninny Power, a joint venture of ESB International and Bord na Móna, the project planned to build 61 turbines with a capacity of 200MW, enough to supply electricity to 100,000 homes.

Located in County Mayo, the Oweninny Wind Farm is one of Ireland’s major onshore wind energy developments. Delivered by Oweninny Power, a joint venture of ESB International and Bord na Móna, the project planned to build 61 turbines with a capacity of 200MW, enough to supply electricity to 100,000 homes.

Phase one involved building 25km of 4m wide unpaved access roads and temporary working platforms at 29 wind turbine locations. The wind farm was constructed on challenging ground, so roads and platforms needed sufficient bearing capacity to support heavy construction traffic over weak and saturated ground, while also being economical to build.

Upon review of the original design proposal, Tensar provided a value engineered solution that maximised the performance of the working platforms and access roads mechanically stabilised by Tensar geogrids. Working platform thickness was reduced by 40% to 50% (depending on ground conditions) while still meeting the loading requirements. The volume of aggregate required was reduced by over 50%, leading to major reductions in CO2 emissions. Key to achieving this figure was the reduction in aggregate truck movements, which for this project was around 550 vehicles. By removing a substantial volume of traffic from rural roads, not only did Tensar contribute towards an environmental solution, but also promoted health and safety benefits.

How Tensar can help you with your next project

This guide has introduced you to how geogrids can make wind farm construction more sustainable, along with the applications they can be applied to. We’ve also discussed how they can drive sustainability through the supply chain while reducing carbon emissions, minimising material use, and protecting sensitive environments.

Our free Tensar+ software can assist you with planning and optimising your wind farm infrastructure, providing insights into how we can support your next project. Tensar geogrids can also improve soil stabilisation, protect sensitive ground such as peat, and minimise environmental disruption – saving you both time and money.

Discover how Tensar could add value to your next renewables construction project. Request a free design assessment or get in touch with our team to find out more.