Road Construction: Pavement Types, Methods, and Designs

Road construction involves the design, building, and maintenance of roads, highways, motorways, and other transportation infrastructure. The aim is to create durable, safe, and efficient routes for vehicular and pedestrian traffic.

In road engineering and construction, the two main types of pavement are rigid and flexible. These two types use different materials and road construction methods, resulting in different physical properties.

This guide introduces you to the fundamentals of road design and construction. It discusses the different road construction methods and the types of pavement involved, along with key design considerations such as how to optimise pavements to reduce costs and carbon footprints.

Read on to learn more about:

- Types of road construction methods

- Types of pavement in road construction (including rigid pavements and flexible pavements)

- Types of road surfaces

- The future of pavements

- The power of pavement optimisation

Use these links to find the section you’re most interested in.

What are the types of road construction methods?

One important point to note is that within the geotechnical engineering industry, the above question usually relates to the different types of pavement construction, rather than road construction. Before we dive in any further then, let’s take a quick look at what pavement is in the first place.

What is a pavement?

The pavement is the part of the road that carries the traffic (not to be confused with the footpath), and has a set of layers or material placed over the natural ground (subgrade). The pavement layers spread the load of the vehicles so that it does not exceed the strength capacity of the subgrade.

The challenge for the pavement engineer designing the road is to select the right material and layer thicknesses so that the pavement will be serviceable for the full design life. When discussing the strength of road paving, we usually measure this in the number of vehicles they can support.

Once we know the requirements of the road paving in terms of supporting traffic and how long it should ideally last, the next step is to set out the specifications for construction. In addition to the materials and layer thickness, the type of pavement (rigid or flexible) is also a key design choice.

Types of pavement in road construction

There are two main types of road surfaces and pavement construction methods: rigid pavement (consisting of one layer) and flexible pavement (typically made up of multiple layers). Pavements are often made of materials such as asphalt or concrete. But they are also other types of road surface materials including artificial stone, flagstone, cobblestone, bricks, tiles or even timber.

Cross section of modern pavements.

(Left) Flexible asphalt-based pavement.

(Right) Rigid Portland cement concrete pavement.

Source: https://www.britannica.com/technology/flexible-pavement

Rigid pavements

When rigid pavements are constructed, a reinforced or unreinforced in-situ concrete slab is laid over a granular subbase. Loads are supported by the flexural strength of the pavement, which acts like a stiff plate, transferring the load over a wider area of subgrade. Concrete roads are a rigid road paving type, and there will usually be joints in the concrete to control cracking.

Much of the US Interstate network and European highway network use concrete construction, although it has been much less popular in the UK. Concrete road pavements can handle very heavy traffic flows and high axle loads. They are now more common in urban areas, ports and locations, where heavy trucks travel slowly. The design life of rigid pavement is typically 40 years, with failure usually occurring due to cracking of the slabs, or degradation at the joints.

Flexible pavements

Flexible pavements are the most commonly used pavement type in road construction in the UK. They typically have multiple layers, often with road asphalt making up surface layers. With flexible pavements, wheel loads are transferred by particle-to-particle contact of the aggregate through the unbound granular layers. The pavement is supported by and protects the subgrade below the pavement.

In asphalt pavement design, asphalt roads are constructed using flexible pavement. Also included within the flexible pavement type are gravel roads, which are common across the globe in rural areas, farm-to-market roads, quarries and access roads.

Tensar+ can help you design your next road project while taking different types of pavement into account.

Access our free Tensar+ software

Flexible road construction

In flexible road construction, one or more layers of selected granular material are laid and compacted over the subgrade. As-dug, naturally occurring materials are often used, but greater performance is gained by using manufactured, crushed aggregates.

With crushed aggregate (unpaved) roads, one or more layers of manufactured, crushed aggregate will form the pavement, with the crushed rock having angular particle shape with a defined range and mix of particle size. The layers are wetted to aid compaction, allowing the particles to interlock and densify. Where multiple layers are used, the lower layer is of a coarser grading, while the upper layer is finer textured granular material.

Bituminous pavements are flexible. Bitumen is used to bind aggregate particles together to form a flexible, strong, and waterproof layer. The mixture of aggregate and bitumen is called asphalt concrete (or asphalt or tarmac for short). Aggregate roads can be given a thin, flexible surface of bitumen-bound stone that will prevent dust, provide waterproofing, reduce maintenance, and provide a safer driving surface. Bitumen is sprayed on and stone chippings spread over the surface and bound in place by the bitumen.

By far the most commonly adopted construction type for urban and network roads is the layered flexible bituminous pavement. The pavement is built up with one or more unbound aggregate layers, the subbase, followed by either an unbound granular base or road asphalt base layer. Above this is the asphalt binder course and finally the asphalt surface course. The base course and binder course provide most of the structural support while the surfacing provides a smooth waterproof riding surface with high skid resistance.

The design life of bituminous flexible pavements is normally 20 years. Failure sometimes occurs due rutting, cracking, or ageing of the asphalt layers or failure of the subgrade leading to deep rutting. Regular maintenance of the surfacing layer can greatly prolong pavement life.

A highway constructed using flexible bituminous pavement

Earthworks in road construction

Earthworks refers to any activity or work that is done to create a space where the roads can be built. Adequate earthworks ensure the longevity of the road being built and help to prevent the need for maintenance and repairs in the future.

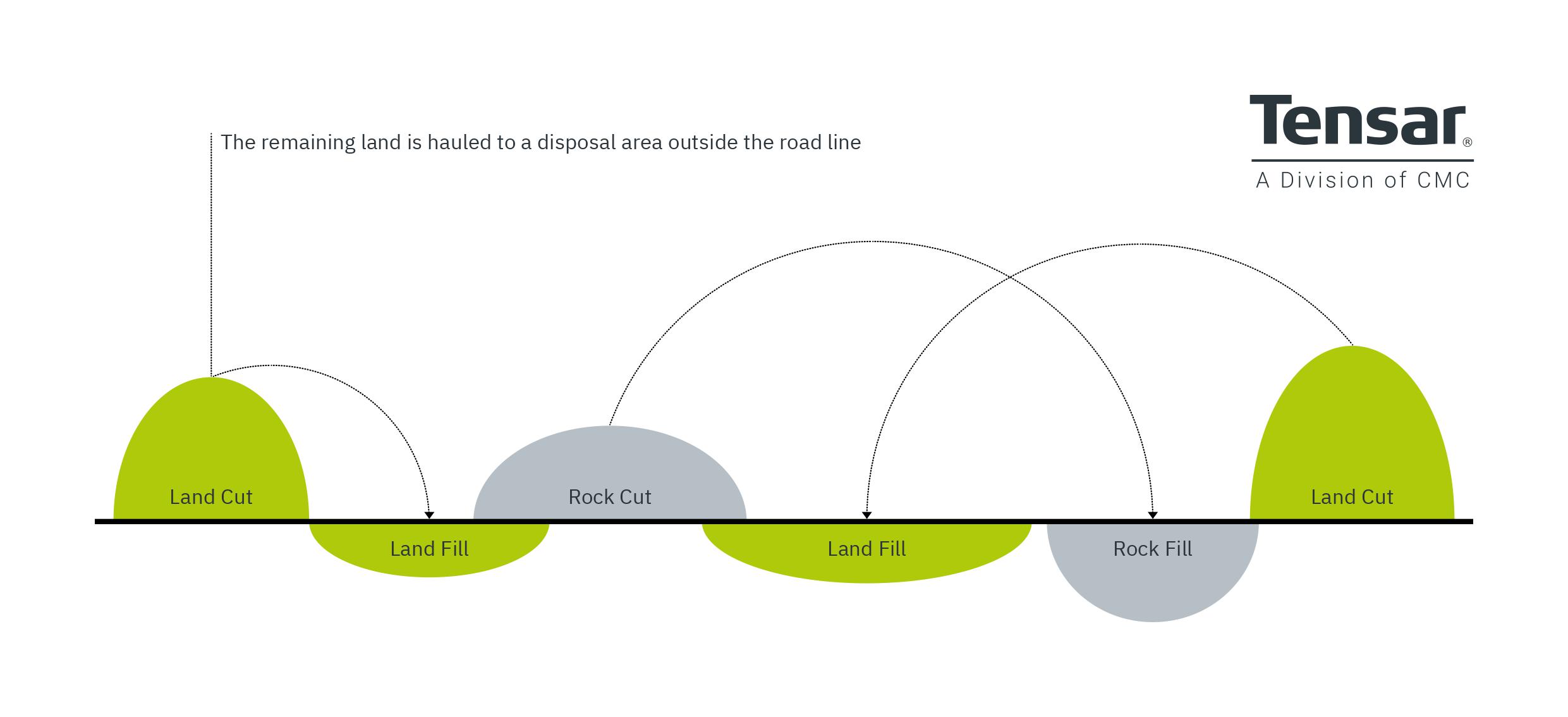

The ‘cut-and-fill’ process is typically used for earthworks in road construction. First, the material is excavated from the site. It is then transported nearby and used to create embankments. The cut-and-fill method minimises the amount of construction labour and conserves the excess material reducing soil disposal.

Road excavation method

Road or highway excavation involves the removal of topsoil and vegetation to expose the desired ‘formation level’. Excavation in road construction is typically done using a bulldozer or tractor shovel. The strength of the subgrade below the formation level will then be tested and stabilised if deemed unstable.

Soil or rock that was removed from its natural location is transported to the fill locations to acheive balances cut & fill earthworks.

Types of road surfaces

We’ve covered the different types of pavement in road construction, how they’re designed and which ones are the most common throughout the UK, but often there are different road surface types that are layered on the top of the road or pavement to prolong its life. Road maintenance companies and councils use these road surface types across the UK:

Road/pavement renewal: full replacement of the road surface type, where existing layers are removed and new ones installed.

Surface dressing: liquid bitumen that's sprayed on existing road surface to extend the life, prevent potholes and reduce slipperiness.

Pavement slurry seal: a mixture of bitumen emulsion, aggregate and water that's sprayed over existing pavements to provide a more even surface.

Re-tread: the existing surface is taken up and recycled by mixing it with bitumen and relaying it before a second surface treatment can be added.

Micro surfacing: an additional asphalt protective seal coating that seals cracks and renews the surface.

The future of pavements

As with all areas of the industry, there is a need for lower cost road construction methods.

One route would be reduced maintenance requirements, which would both reduce operating costs and minimise traffic disruption on congested networks.

A second option would be to increase pavement life, thereby also enhancing sustainability. This might be achieved by using less non-renewable materials, reducing the carbon emissions generated during construction and maintenance, as well as reducing traffic delays which themselves increase carbon emissions and local air pollution.

And a third, key possible way forward is that greater resilience of pavements would make them less susceptible to the effects of climate change, such as increased frequency and intensity of storms in addition to higher and lower air temperatures.

Tensar InterAx helps to reduce the pavement depth at North Heybridge Estate Road with estimated savings of £177,000

The power of pavement optimisation in road construction

As mentioned above, the future of pavements lies in optimisation. Pavement optimisation aims to construct high-performing road pavements quickly and economically, often utilising geogrids for mechanically stabilised aggregate layers. This approach, crucial for flexible pavements, controls aggregate displacement and delays the onset of failure in the structure.

Tensar coined the term ‘pavement optimisation’ in reference to its economical design principles. To optimise pavement, we need to strike a balance between reduced thickness and enhanced traffic performance, saving materials and typically reducing costs by 20%. This not only lowers the overall expenses but also extends pavement life, sparing expense in the long run. Moreover, designing modern, optimised pavements is kinder to the environment, reducing the carbon footprint of road construction projects.

Now you know that pavement optimisation is a smart and cost-effective way to make roads last longer, cost less, and have less of an impact on the planet, let’s explore some specific practical examples.

Road stabilisation

In road construction, encountering weak or variable ground can prompt the adoption of road stabilisation – an alternative to excavating and replacing the subgrade. This method involves modifying subgrade soil properties by adding a stabilising lime cement, or other chemical agent, mixed in-situ. For a comprehensive understanding of various road stabilisation techniques, delve into this informative guide on road stabilisation methods and their applications.

A more sustainable and cost-effective approach can be to place a stronger soil layer, typically compacted aggregate material, over the weak soil to distribute load. This enhances bearing capacity, often incorporating a geosynthetic at the subgrade level. Incorporating geogrids for road and pavement stabilisation further reinforces the efficiency of the road, offering a versatile solution for challenging ground conditions.

This approach reinforces road efficiency whilst minimising the need for extensive excavation, offering a versatile solution for challenging ground conditions. .jpg)

confinement of aggregate particles with Tensar Interax geogrid

Accelerated Pavement Testing (APT)

Accelerated pavement testing (APT) is a method that assesses long-term pavement performance in a condensed time frame. By applying realistic wheel loading to a layered pavement structure, APT simulates extended in-service traffic conditions to evaluate pavement response and performance efficiently.

The accumulated damage from multiple wheel passes on different layers influences the pavement’s overall performance and eventual failure. Unlike assessing individual layers or materials in isolation, accelerated pavement testing provides the only realistic means to determine the long-term performance and lifespan of the entire pavement structure.

To gain in-depth insights into accelerated pavement testing, explore our detailed article covering the methodology, execution, and valuable findings from this crucial aspect of pavement optimisation.

APT testing in progress using a reciprocating dual wheel tandem axle

Geogrid pavement design

Geogrid pavement design is a strategic approach to constructing optimised road pavements, leveraging geogrids to enhance stability and longevity. Geogrids are engineered materials integrated into pavement layers, providing mechanical stabilisation to aggregate materials.

This design methodology aims to distribute loads more effectively, minimising rutting and fatigue cracking, whilst also preventing moisture and contaminants from compromising the pavement structure. Geogrid pavement design proves essential for a range of flexible pavements, ensuring durability and performance. For an in-depth exploration, refer to this insightful resource on geogrid pavement design..jpg)

Site support facilities swiftly establised by using Tensar InterAx geogrid

Highway innovation

Highway innovation involves breaking down barriers to embrace advancements in the construction of highway networks, ensuring that standards align with technical progress. Incorporating innovation in highway design involves adapting to actual ground conditions, offering more fitting solutions, mitigating risks, and enhancing overall value.

This shift doesn’t necessarily mean increased costs but demands a change in approach and broader acceptance of ‘alternative’ designs. An example of innovative design lies in geogrids for road pavement and highway construction. For a deeper exploration of highway innovation and insights on overcoming barriers, explore our dedicated article shedding light on the challenges and advancements in highway innovation.

Want to learn more about pavement design?

Eager to deepen your understanding? Explore our other pavement design articles:

Have an upcoming project and require expert support? our design team are here to help.

Get in touch

.png?width=400&height=400&ext=.png)