The power of Pavement Optimisation

by Michal Golos, on May 01, 2020

Pavement Optimisation, using geogrids to create mechanically stabilised aggregate layers, delivers high performing road pavements quickly and economically, while minimising environmental impact.

Regular readers of this blog will know that an aggregate layer incorporating a Tensar geogrid performs as a composite, due to the interlocking mechanism and particle confinement that develops between the granular particles and the geogrid under loading. This ‘mechanically stabilised layer’ increases bearing capacity over any type of ground and can help mitigate total and differential settlement.

Pavement Optimisation

When it comes to flexible pavements – anything from a car park to a major highway construction project – mechanically stabilised layers in the pavement structure can delay the onset of failure, by controlling lateral and vertical displacement of aggregates from traffic loads. Aggregate stabilisation with geogrid results in increased stiffness of a layer, and this has a significant impact on pavement life. Pavement rutting and asphalt fatigue cracking are reduced, and additionally this helps to prevent moisture and contaminants entering and weakening the pavement structure.

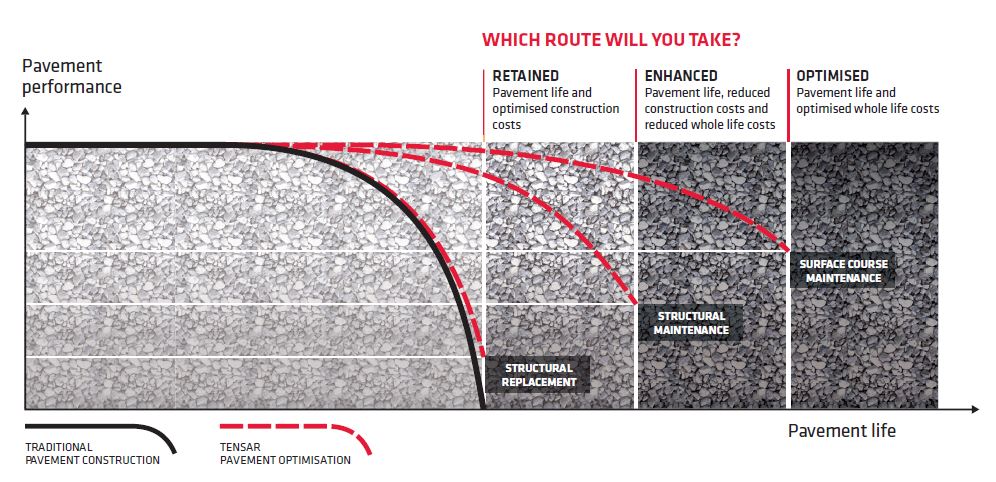

We call this approach ‘Pavement Optimisation’ because it enables engineers to deliver a design that meets a project’s priorities in the most economical way, striking a balance between reducing pavement thickness with increased trafficking performance. Pavement Optimisation gives designers three choices:

- To retain pavement life and optimise construction costs

- To enhance pavement life and reduce construction costs and whole life costs

- To optimise pavement life and whole life costs.

These options are simply illustrated in the following diagram:

The benefits of Pavement Optimisation

Broadly speaking, there are four key benefits of Pavement Optimisation:

- Reduced pavement costs: Construction costs are typically cut by up to 20%, by using fewer materials and accelerating construction programmes, while maintaining trafficking performance

- Increased pavement life: Traffic capacity can be increased by up to six times that of traditionally-built pavements

- Lower whole-life costs: Increased trafficking performance can reduce maintenance and repairs, delivering whole-life cost savings

- Reduced carbon footprint: Road construction materials have high embodied energy in terms of CO2e emissions. Reducing the amount of materials used in the road construction can reduce a project’s carbon footprint.

Delivering a thinner, better performing pavement for the Great Yorkshire Way

Construction of the pavement on the Great Yorkshire way scheme

Construction of the pavement on the Great Yorkshire way scheme

Doncaster Metropolitan Borough Council asked us to come up with an alternative road pavement design for the Finningley and Rossington Regeneration Route Scheme (FARRRS - now the Great Yorkshire Way), to help cut construction costs, while increasing the road’s service life.This is an effective use of value engineering, cutting costs while improving its value and functionality.

The Great Yorkshire way runs south of Doncaster between junction three of the M18 and Robin Hood Airport, with links to Rossington and a major distribution hub, iPort.

Conventional pavement design would have involved lime/cement stabilisation of the ground beneath the route, which had an average CBR of between 3-5%. By adopting our Pavement Optimisation approach, incorporating stabilising geogrid in the road pavement structure, the Council was able to reduce overall pavement thickness by a quarter, saving £500,000 on construction costs, while improving the road service life by an average of 60%, resulting in cost savings throughout the life of the road.

Read the case studies in detail:

- Success stories: Great Yorkshire Way

- Success stories: FARRRS

Reduce maintenance requirements and enhance the service life of asphalt pavements with Tensar's asphalt interlayers.

Learn More